Running a food business in the UK requires adhering to strict food safety standards to protect your customers and fulfil your legal obligations. From restaurants and cafés to catering services and takeaways, maintaining high levels of hygiene and safe food handling is essential to avoid health risks and regulatory consequences.

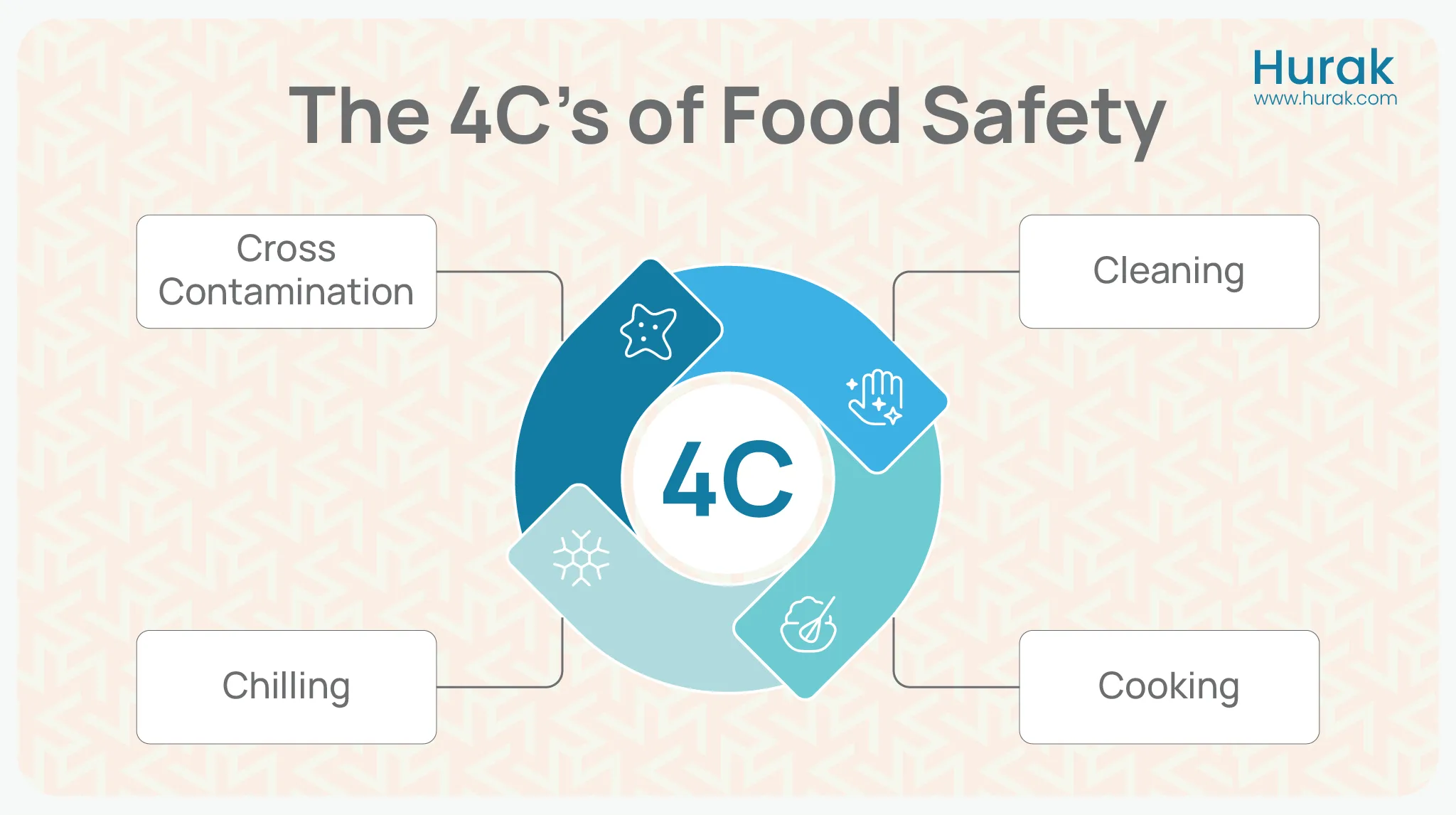

The 4Cs of food safety — Cleaning, Cooking, Chilling, and avoiding Cross-contamination — are key principles promoted by the Food Standards Agency (FSA). They provide a clear and practical framework for managing food safety throughout every stage of food preparation and service.

Although the 4Cs themselves aren’t explicitly outlined in legislation, the practices they support are fundamental to complying with UK food laws, including the Food Safety Act 1990 and the Food Hygiene Regulations 2006. Failing to implement these practices can lead to foodborne illnesses, poor hygiene ratings, and legal action.

In this article, we’ll break down each of the 4Cs, explore why they’re so important for food businesses, and offer practical tips to help you apply them in day-to-day operations.

But first, let’s look at why these four principles are considered essential across the UK food industry.

Why Is Following the 4Cs Important for Food Businesses?

What are the 4Cs of food safety, and why are they important?

Simply put, they are Cleaning, Cooking, Chilling, and avoiding Cross-contamination, four essential principles that safeguard food safety and help UK businesses comply with legal and hygiene standards.

The 4Cs aren’t just a checklist; they form the foundation of safe food handling by reducing health risks, supporting legal compliance, and ensuring you’re prepared for inspections.

Here’s how each of these principles reinforces why the 4Cs should be at the heart of every UK food business.

They Reflect FSA Guidelines and Expectations

The Food Standards Agency (FSA) strongly promotes the 4Cs because they provide a clear foundation for safe food handling and hygiene. While not explicitly mentioned in the law, the FSA considers the 4Cs to be essential to good food safety practices, and inspectors will expect to see them applied in kitchens, storage areas, and front-of-house environments.

Following the 4Cs can also help businesses achieve a better food hygiene rating, which in turn influences customer trust and reputation

Ignoring the 4Cs Increases Health Risks

When businesses don’t follow the 4Cs, they increase the risk of foodborne illnesses caused by harmful bacteria like Salmonella, Listeria, or E. coli. Cross-contamination, incorrect cooking temperatures, or inadequate chilling can all contribute to the growth and spread of these pathogens, posing a serious risk to your customers’ health.

There Are Serious Legal Consequences

Although the 4Cs themselves aren’t written into legislation, the practices they represent are enforceable under UK food law. The Food Safety Act 1990 requires all food businesses to produce and serve food that is safe to eat. Failure to control food safety hazards could result in prosecution, fines, business closure, or even imprisonment in serious cases.

Helps You Stay Inspection-Ready

Food safety inspections don’t happen on your schedule; they can occur at any time. Following the 4Cs ensures you’re prepared, with strong cleaning routines, proper temperature control, labelled storage, and clear procedures in place. This makes risk assessments easier and helps maintain compliance across your team.

For detailed guidance on how to be prepared for a Food Safety Inspection, read our article on the food hygiene rating checklist.

Incorporating the 4Cs into your daily operations isn’t just about passing inspections; it’s about building a food safety culture that protects people, supports your brand, and reduces long-term risks.

Now let’s look more closely at each of the 4Cs in action.

🎓 Ready to upskill your staff or meet legal training requirements?

Start with a certified course: 👉 Level 2 Food Hygiene and Safety for Catering 👉 Level 2 Food Hygiene and Safety for Retail

The 4Cs of Food Safety

Now that we’ve explored why the 4Cs matter, let’s look at each one in practice. Together, they create a strong framework that protects food from common hazards, but each one plays a unique role in keeping your premises inspection-ready and legally compliant

Cleaning

Cleaning is the first and arguably the most continuous step in food safety. It’s about creating and maintaining a hygienic environment, not just at the start or end of the day, but throughout the entire day.

- A clean-as-you-go approach ensures that spills, food scraps, and splashes are addressed promptly. Why wait until the end of a shift to wipe down a counter that’s been touched dozens of times? By cleaning as you work, you prevent harmful bacteria from building up and spreading to food or equipment. It’s proactive, not reactive.

- Go beyond a simple wipe-down. The six stages of cleaning are key: pre-clean, main clean, rinse, disinfect, final rinse, and drying. These aren’t just steps, they’re safeguards. Miss one, and you risk leaving behind dangerous residues or ineffective sanitisation.

- Use colour-coded chopping boards to separate raw meat, cooked food, dairy, and vegetables. It’s a small thing that goes a long way in reducing cross-contamination, especially when multiple people are prepping in a busy kitchen.

- And don’t overlook the basics: hand hygiene. Hands can transfer thousands of bacteria in a single touch. Follow the 7 steps of hygienic hand washing, especially after handling raw foods, using the toilet, or taking out the bins.

- Lastly, wash fruits and vegetables under running water before cooking or serving. This removes dirt and pesticide residues, but do not wash raw meat; it can splash bacteria across your sink and counters, increasing the risk of contamination.

Cooking

Cooking is more than getting food hot, it’s your defence against harmful microorganisms like Salmonella or E. coli. If meat isn’t cooked properly, these bacteria can survive and cause serious illness.

- Every food type has its specific requirements. The core cooking temperature generally recommended is 75°C; however, checking with a food probe is the most reliable way to ensure the food is safe. You should always be aware of the Temperature Danger Zone while cooking.

- If you’re cooking something with packaging (like a frozen pie or pre-made meal), follow the manufacturer’s guidelines. But if there are no instructions, stick with FSA advice, especially for:

- Poultry (chicken, duck, turkey)

- Pork

- Minced meats (like sausages, kebabs, burgers)

- Offal (liver, kidneys)

- Rolled joints, where bacteria can be pushed from the surface into the centre during preparation

These foods are considered high-risk because they’re more likely to carry harmful bacteria. That’s why undercooking them isn’t just a mistake, it’s a danger.

Poor cooking practices can also breach the Food Safety Act 1990. If your food harms someone, even unintentionally, the consequences are legal.

Chilling

Chilling slows down the growth of bacteria, but only if it’s done right.

- It is essential to understand the ideal fridge storage temperature and make sure your fridge is set to 5°C or below. Also, never overload your fridge. Cold air needs space to circulate; otherwise, certain spots warm up, creating the perfect breeding ground for bacteria.

- Always store raw meats on the bottom shelf of the fridge to prevent their juices from dripping onto ready-to-eat foods, which can lead to cross-contamination and serious foodborne illnesses. For tips on safe fridge storage, see our full guide on how to organise a fridge.

- Understand the food dates. A “use-by” date is about safety; eat it after that and you’re taking a risk. A “best-before” date, on the other hand, is about quality. It is crucial to be aware of the difference between use-by and best-before date.

- When it comes to leftovers, many wonder: Can you put warm food in the fridge? The answer is yes, but let it cool slightly first — ideally for no more than 1–2 hours. Placing steaming food directly into the fridge can raise its internal temperature and potentially affect other items stored nearby.

- Understand your freezing limits, too. Beef and other meats can only last a certain amount of time, even when stored in the freezer. Learn how long you can safely freeze food, the best methods for cooking it from frozen, and how to defrost it properly.

Cross-Contamination

Cross-contamination is silent and quick. A knife used for raw chicken, then reused for salad without washing, that’s all it takes.

To protect food from cross-contamination:

- Always use separate equipment and colour-coded boards for raw and cooked food.

- Store raw food below cooked food in the fridge to prevent drips.

- Wash your hands every time you switch tasks.

- Clean and disinfect surfaces between jobs.

- Be aware of cross-contact, especially when it comes to allergens, as even a trace can trigger a serious reaction.

- Understand the different types of contamination:

Advance Your Food Safety Skills With Professional Training

Understanding the 4Cs is essential, but it’s only the beginning. To truly lead safe, compliant food operations, especially in supervisory roles, formal training is a must.

📚 Level 3 Food Hygiene and Safety Course

Ideal for managers and supervisors, this course dives deeper into food law, risk assessments, and hygiene practices, helping you implement the 4Cs across your team and stay compliant with UK regulations.

🥜 Food Allergy Awareness Course

Allergen cross-contact is a serious risk. This short course trains you to identify, label, and control allergens in food preparation — a vital extension of your cross-contamination strategy.

Take charge of food safety today!

Going Beyond the 4Cs: Best Practices to Prevent Food Safety Failures

Now that we’ve seen how each of the 4Cs plays a role in preventing foodborne risks, let’s shift focus to the broader strategies businesses can adopt to keep those risks at bay—before they even start.

Here are three proven ways to stay proactive about food safety compliance:

- Implement a HACCP Plan

Hazard Analysis and Critical Control Points (HACCP) is more than just a checklist—it’s a structured system designed to identify, assess, and control food safety risks at every stage of your operation. From storage to service, every potential hazard is identified and managed effectively. - Stay Inspection-Ready at All Times

Waiting until an EHO visit is announced is a recipe for panic. By maintaining your premises, documentation, and adhering to food safety protocols on a daily basis, you ensure that you’re always prepared for a spot check. This includes having updated cleaning logs, temperature records, and allergen labelling processes in place. - Invest in Regular Staff Training

Even the best systems fall apart without well-trained staff. Ongoing training ensures that your team is confident in consistently applying the 4Cs. Refresher sessions are especially crucial in high-turnover environments, such as the hospitality industry. A simple misunderstanding of cross-contact, for example, could put a customer with allergies at serious risk.

- Implement a HACCP Plan

HACCP Training for Safer Premises

Learn how to assess food safety risks, apply adequate controls, and keep your kitchen inspection-ready with Hurak’s Level 2 HACCP Course.

Incorporating these measures won’t just help you avoid food safety issues; they’ll help you build a culture of accountability across your team.

Let’s now understand how things can quickly go wrong when even one of the 4Cs of food safety is ignored, with an example.

This example shows how one small lapse in chilling can escalate into a serious breach, reinforcing why every C counts.

How a Small Oversight Can Lead to a Major Food Safety Breach

Let’s examine a scenario that could occur at any food outlet, where a minor lapse in judgment puts customer health at risk.

Note: This example is provided for educational purposes only.

Scenario: A Busy Café and a Chilling Oversight

In a small high-street café, the kitchen staff cooked large batches of minced beef chilli during morning prep. Due to time pressure and limited fridge space, hot food was placed directly into the fridge to cool faster. Later that evening, several customers reported symptoms of food poisoning. An investigation by local authorities revealed that the food had spent too long in the temperature danger zone—between 8°C and 63°C. Allowing bacteria like Clostridium perfringens to multiply. No chilling logs were maintained, and the team was unaware of proper cooling procedures.

What went wrong?

A failure to follow safe chilling practices, one of the 4Cs, triggered a chain reaction, demonstrating how a single oversight can impact public health, damage your brand reputation, and result in legal action.

The story also illustrates why understanding guidelines isn’t enough; you must apply them, monitor their implementation, and train your staff to do the same.

Conclusion: Food Safety is a Constant Commitment

Mastering the 4Cs —Cleaning, Cooking, Chilling, and Cross-Contamination —forms the backbone of any safe food environment. But food safety doesn’t end there.

To truly protect your customers and reputation, you must go the extra mile.

Consider TACCP and VACCP strategies to protect against intentional food threats, or implement regular risk assessments to identify vulnerabilities before they cause harm. Leveraging smart kitchen technology for temperature logs and hygiene audits can also add precision and confidence to your operations.

Whether you run a food truck or manage a full-service kitchen, your safety systems must evolve with the industry. When done right, these steps not only reduce risk but also boost customer trust and business resilience.

Go Beyond the 4Cs – Train Smarter

Master legal compliance, inspections, allergen safety and more with Hurak’s CPD-certified Food Hygiene and Safety Courses.

FAQs

What are the 4Cs of food safety, and why are they important?

The 4Cs of food safety are Cleaning, Cooking, Chilling, and avoiding Cross-contamination.

They are important because they form the foundation of safe food handling practices, helping to prevent foodborne illnesses, protect public health, and ensure compliance with UK food safety laws. By following the 4Cs, food businesses can reduce health risks, maintain hygiene standards, and pass inspections with confidence.

How can I train my staff on the 4Cs?

Enrol them in a certified Food Hygiene Course, such as Hurak’s Level 2 or Level 3 programmes, which cover the 4Cs in depth.

Is it mandatory to follow the 4Cs in a home kitchen?

While not legally required for home use, following the 4Cs helps protect your family from harmful bacteria and ensures safer food practices.

Are there practices beyond the 4Cs that I should know?

Yes, advanced methods such as TACCP, VACCP, digital temperature monitoring, and regular risk assessments extend beyond the 4Cs to address intentional food threats and complex safety risks.