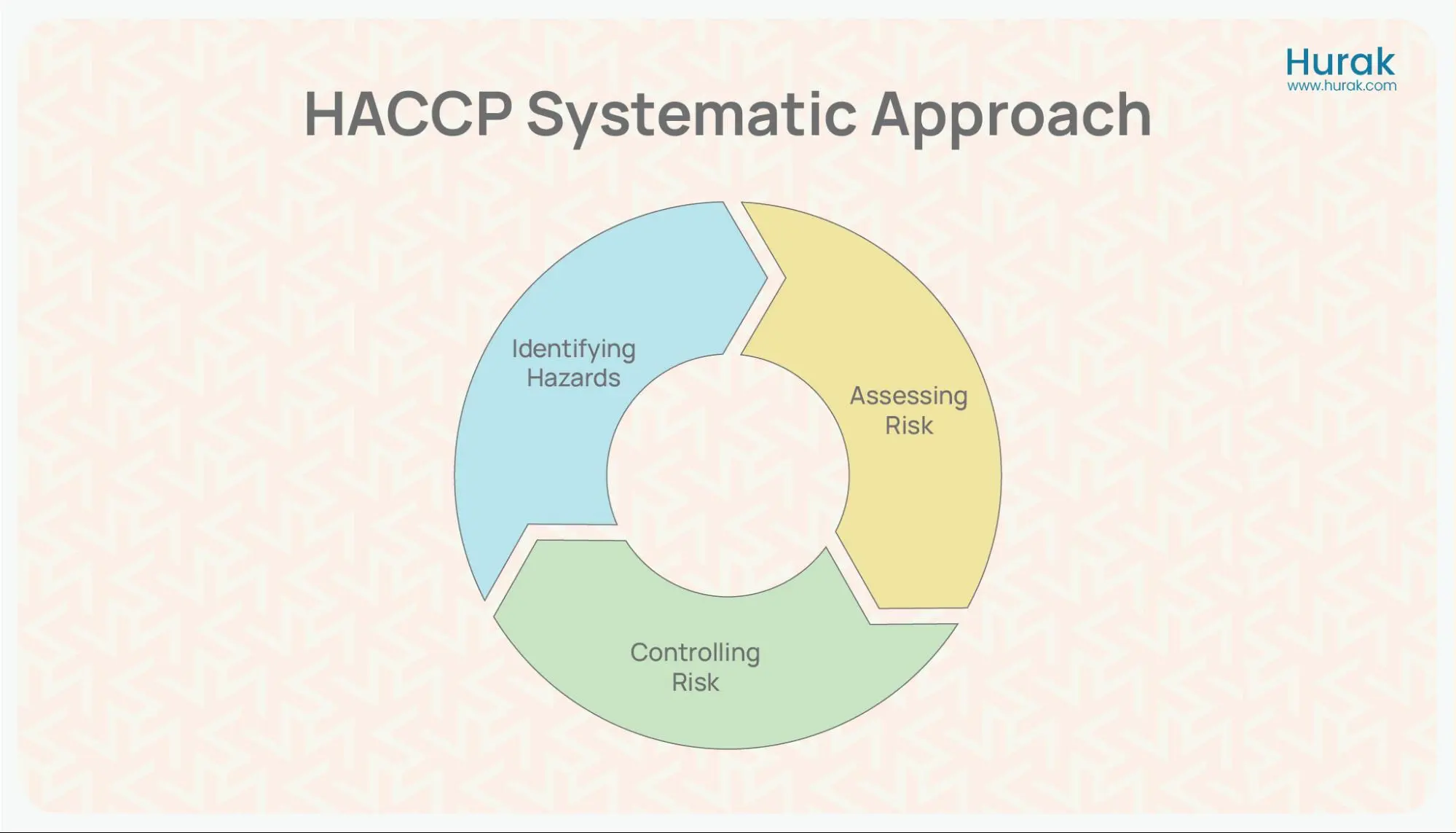

The HACCP is a contamination control procedure applied across all stages of the food supply chain to assess and control potential risks. It is the primary risk management process of food safety. The HACCP system provides a systematic preventive approach for food-related contaminants and mishaps.

Explaining the Acronym: HACCP

HACCP stands for Hazard Analysis Critical Control Point.

Hazard

Hazards are possible risks in the form of pollutants or unacceptable material and unsafe practices in the food production system. They can affect the safety, quality, and purity of the food product. Hazards include microbial, physical, chemical, and allergenic contaminants. The entry of pollutants through cross-contamination in food is another hazardous risk to food safety.

Analysis

Hazards identified in the food preparation process undergo standardised examination. This occurs through a series of regulated steps. Critical points for hazard entry and damage are predictively marked to proactively control them.

Critical Control Point

All points in the food production stage where corrective measures are applied are critical control points (CCPs). These are contamination control measures that reduce the risk of food-related complications. CCPs look for ‘critical dangerous areas’ and aim to eliminate them.

The HACCP System for Food Safety

The HACCP system monitors and supervises food quality throughout the food production chain, from food processing to food service. It puts in place preventive controls to eliminate potential adverse risks from the food system.

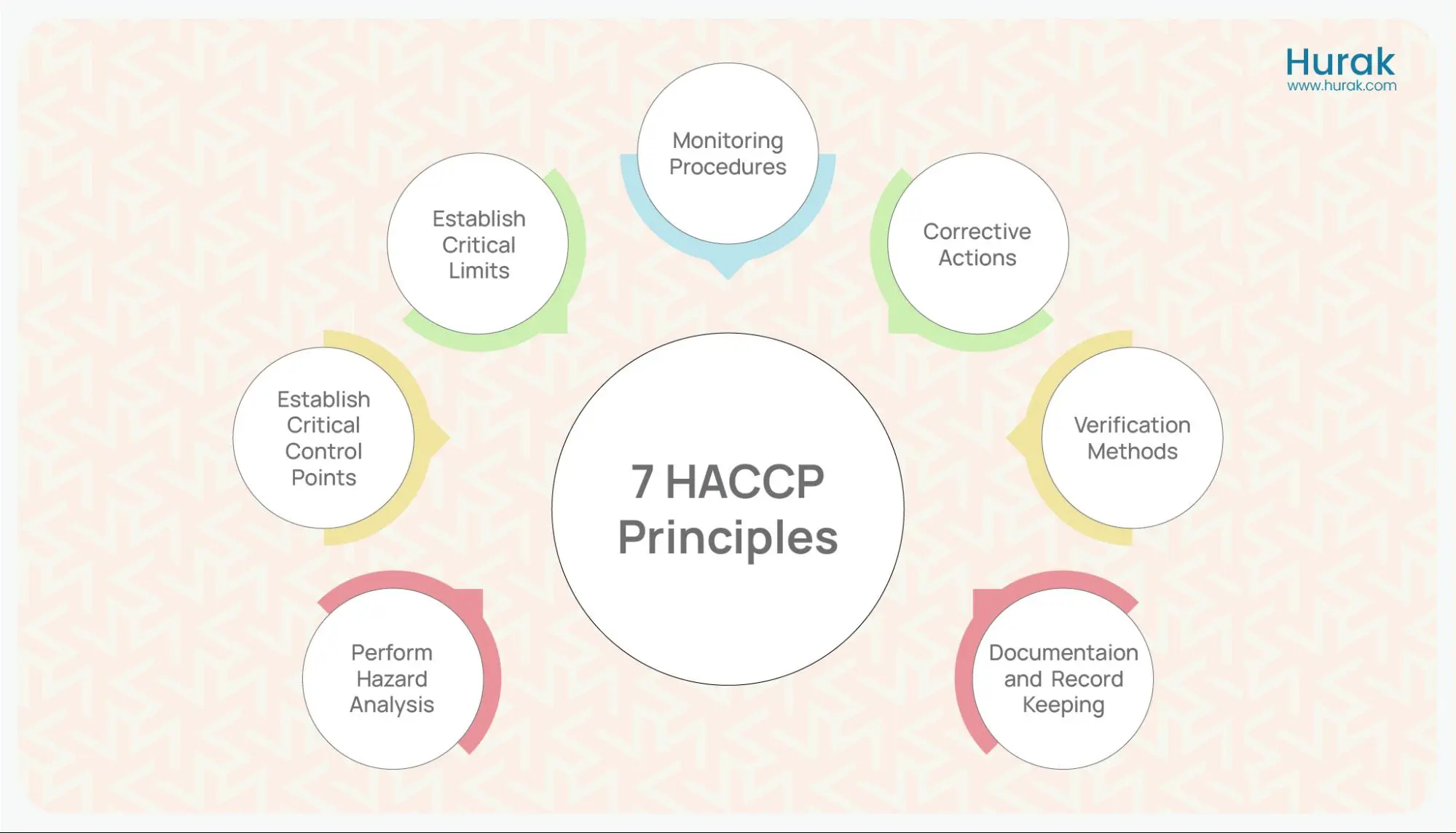

Application of the HACCP system for food safety includes seven important steps, also known as the seven HACCP principles. The principles of the HACCP system identify and eradicate physical, microbiological and chemical pollutants that may have occurred due to cross-contamination or cross-contact contamination.

HACCP is more of a preventive approach than a responsive one. It predicts areas of unsafety in the food production cycle and charts out a plan to control them on time. It focuses more on in-process hazard control than finished product analysis.

Get Online Food Safety Courses

Food Hygiene And Safety

Check the CourseRated Excellent

on major review sites

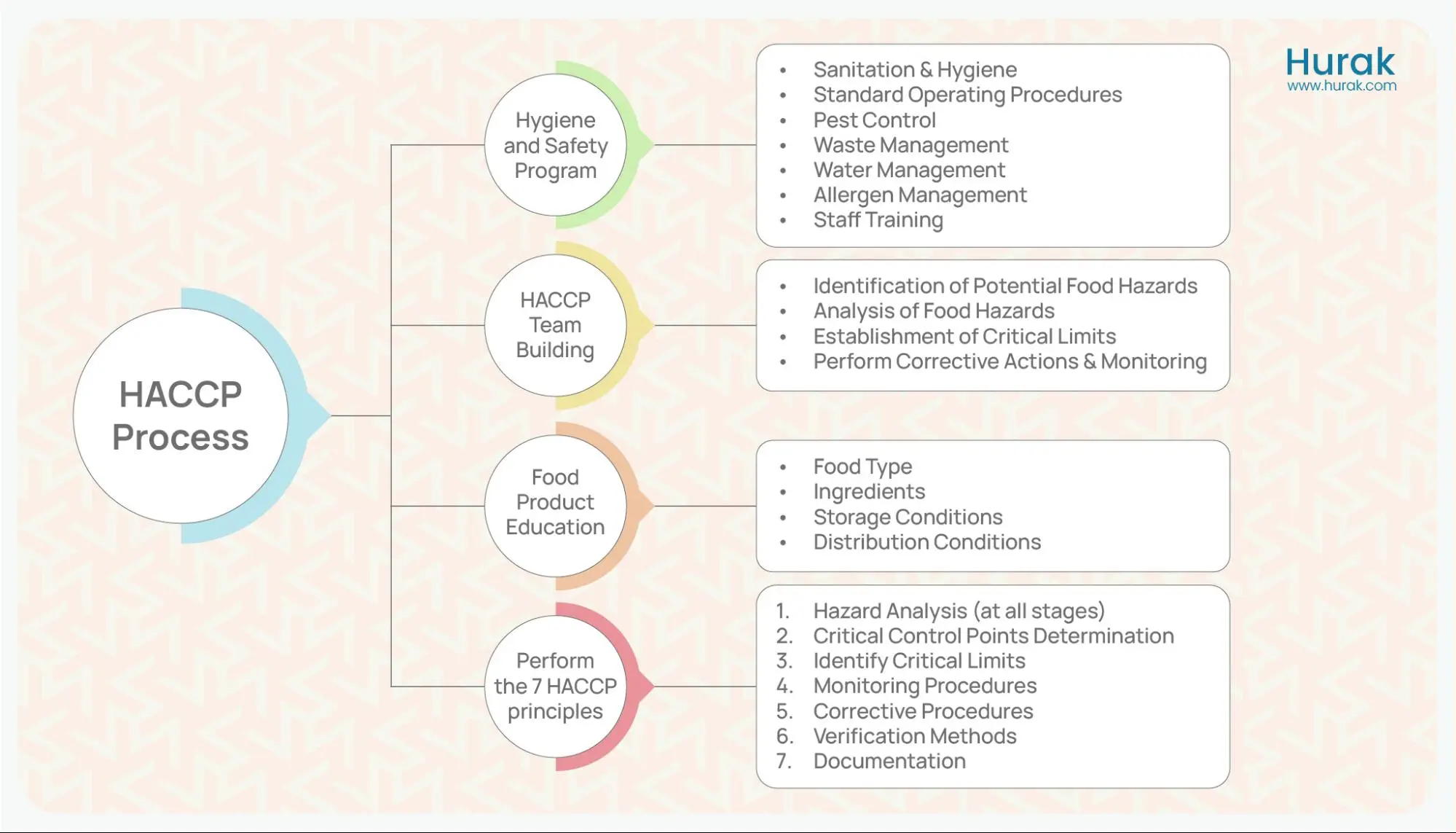

The Process of the HACCP System

The main steps to implementing the HACCP plan include creating the required sanitation and hygiene programs. This is followed by building a team of competent people responsible for carrying out the HACCP plan. Educating the team about the food product they are dealing with is important. This should include information about the type of food, its ingredients, customer assessment, storage, and distribution conditions. The last and most important step in the HACCP system is implementing the seven HACCP principles.

The 7 Principles of the HACCP Process

Principle 1: Perform Hazard Analysis

Hazard analysis and identification are conducted for all stages of the food production process. Special attention is given to areas where hazards are most likely found. If not controlled, hazards can cause injury or illness. Performing hazard analysis is the most important step of the HACCP system. It allows necessary preemptive actions to be taken. For hazard listing and assessing control measures, emphasis is placed on the following areas:

- staff competence in assessing any potential hazard

- conditions for food transportation

- food quality and ingredients for young, elderly and immune-sensitive people

- food storage conditions

- hygiene of food handlers

- equipment maintenance and sanitation

Some common examples of analysing hazards include:

- Microbes are found in stored raw meat due to unsuitable temperature conditions.

- Peanuts containing food delivered to allergic customers.

Principle 2: Establish Critical Control Points (CCPs)

Critical Control Points refer to those potentially dangerous areas in the food system that should be promptly addressed and controlled. They are control procedures that reduce contaminants and risks identified during the hazard analysis stage. The hazards are brought to a minimum level until they are eliminated from the food production chain.

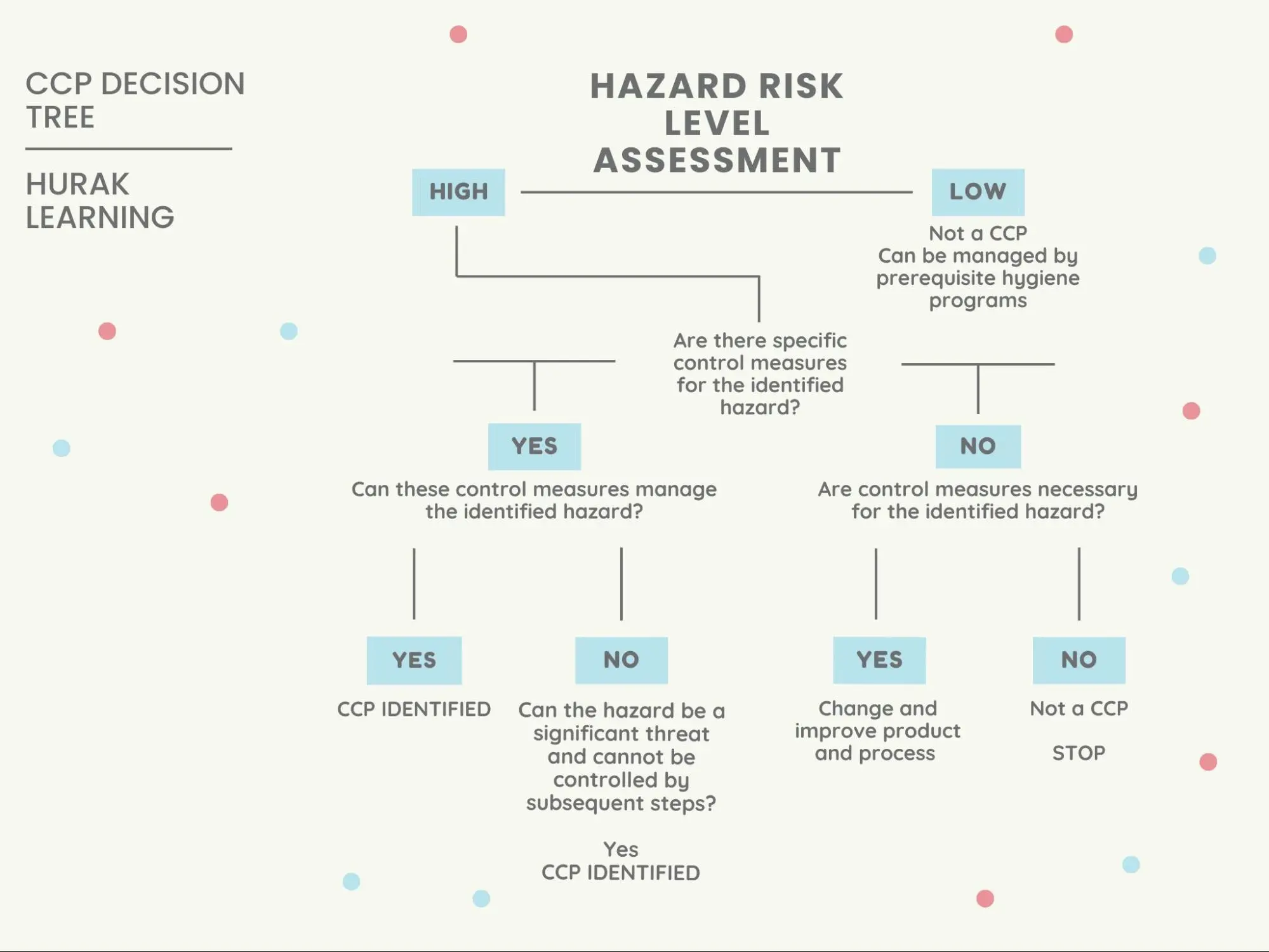

The CCP Decision Tree

The HACCP team uses a hierarchical decision-making map known as the ‘Critical Control Point Decision Tree’ to identify crucial areas of concern in the food safety process. It consists of a series of questions that lead to an informed decision about whether a particular identified hazard should be managed as a critical control point.

Principle 3: Establish Critical Limits (CLs)

Critical limits are established in response to the critical control points to regulate and manage the identified hazard. These limits are measurable and assessed to ensure the threat remains within the bounds established by the HACCP team. Limits can be set for variables to which food is exposed, such as temperature, pH, time, and moisture content.

Some common examples of setting critical limits include:

- The critical limit for reheating temperature for food leftovers is 74°C or 165°F in microwaves and on stovetops.

- The critical limit for fridge storage temperature for food is between 0 °C and 4°C.

Principle 4: Monitoring Procedures

The HACCP team must monitor and supervise the identification of Critical Control Points and the application of subsequent critical limits. Proper monitoring procedures are implemented to ensure the hazard is dealt with effectively.

If any deviation from the standard critical limit is recorded, the monitoring staff takes the necessary steps to correct the irregularity. The HACCP principles’ monitoring procedures uphold food safety and quality standards.

Some common examples of performing monitoring procedures include:

- Monitoring the reheating temperature for food leftovers based on the set critical limits.

- Monitoring the fridge storage temperature for food based on the set critical limits.

Principle 5: Corrective Actions

If the critical limits set for the critical control points are not followed, corrective actions are performed to re-standardise the process. Errors are reported at the monitoring stage, and measures are taken to resolve them.

Some common examples of performing corrective actions include:

- Discarding food stored at room temperature for more than two hours.

- Proper identification of food allergens on non-packaged and packaged food.

Principle 6: Verification Methods

The HACCP system is a scientific plan that can be measured, assessed, and verified. It is important to holistically evaluate the program to determine its reliability and validity. Frequent observations, recording, and monitoring of the HACCP plan can help make necessary changes and improvements.

For a thorough verification process, the HACCP team can run a survey among customers and employees. The survey will contain relevant questions about the quality of the end product and areas of concern in the food production chain. This approach will maintain a constructive feedback loop about the effectiveness of the HACCP program.

Principle 7: Documentation & Record-Keeping

Careful documentation is key for the successful operation of any program. It helps assess progress and continuous improvements made at each plan step. Similarly, the HACCP system’s record-keeping is important. This is to confirm that the established standards for food safety and hygiene are met along different stages of the food supply chain.

Documentation can be written by a trained team member by hand or digitally in the form of a central database, accessible to all members of the HACCP team. This will confirm transparency and accountability. Record keeping can include subjects ranging from basic hygiene measures to implementing critical limits.

Space Food: The Birth of the HACCP System

HACCP was an outcome of the Cold War when the space race between the US and USSR was at its peak. It was initiated to provide safe and hygienic food to astronauts for space expeditions. National Aeronautics and Space Administration (NASA), the Pillsbury Company, and the U.S. Army Laboratories worked together to find a standardised method of confirming food safety to be sent to outer space missions.

The Critical Control Points (CCPs) system was historically related to NASA’s engineering management system. It tested the durability of American weapons and machinery by marking areas of failure and mapping out their control plan. This similar approach was further applied to space-related food safety management. In 1997, it expanded into the HACCP system for food safety management and is still practised today.

FAQs

What does HACCP stand for?

HACCP stands for Hazard Analysis Critical Control Point.

What is HACCP?

The HACCP is a contamination control procedure applied across all stages of the food supply chain to assess and control potential risks. It is the primary risk management process of food safety.

How many steps must be followed in a HACCP system?

The HACCP process has four steps. The HACCP has seven principles that are included in the HACCP process.

What is HACCP in food?

HACCP is the primary risk management process for food safety. The HACCP system provides a systematic preventive approach to food-related contaminants and mishaps.

What is HACCP designed to control?

HACCP is more of a preventive approach than a responsive one. It predicts areas of unsafety in the food production cycle and charts out a plan to control them on time.

Conclusion

The Hazard Analysis Critical Control Point (HACCP) is fundamental to food safety management. It was initially developed for food safety in space missions for the United States. However, it has now evolved into a universal standard for identifying and addressing risks associated with global food production. Implementing the HACCP process and principles allows proactive steps to be taken against the identified food-related hazard.