When there is a workplace or an employee who does, there are products and chemicals that can affect the environment and the way we live and work. These products include, but are not limited to, cleaning products, paint formulations, adhesives and printer toner, as well as any other chemical substances that could be harmful to your health. The Control of Substances Hazardous to Health (COSHH) Regulations 2002 in the UK provide a guideline on the steps that employers need to take to ensure that their employees are protected from the associated risk of working with hazardous substances; however, to maintain the appropriate level of COSHH compliance, there are eight steps that every employer in the UK can take to avoid liability.

What is COSHH and Why Does It Matter

COSHH stand for (Control of Substances Hazardous to Health). COSHH is a series of UK regulations that require employers to ensure the safety of their employees from substances that could harm their health, e.g., chemicals that can cause burns or long-term respiratory problems.

- Employers must identify all hazardous substances used/created in the workplace.

- Assess the risk of how these substances could cause harm to the employee’s health.

- Implement measures to reduce or remove the risk.

- Monitor exposure levels and provide/sustain safe working conditions.

If an employer does not comply with the COSHH regulations, they could face enforcement action, fines, and/or cause an employee to suffer from ill health. However, complying with COSHH can still be very simple. By following the recognised COSHH steps, you will ensure your employees’ safety and adhere to the law.

Looking to Strengthen Your COSHH Knowledge

Want to ensure your workplace meets every COSHH requirement confidently?

Explore our Health and Safety Courses, including COSHH Awareness Training, Risk Assessment Courses, and more, to help you stay compliant and protect your team effectively.

How Many Steps Are There to COSHH Compliance?

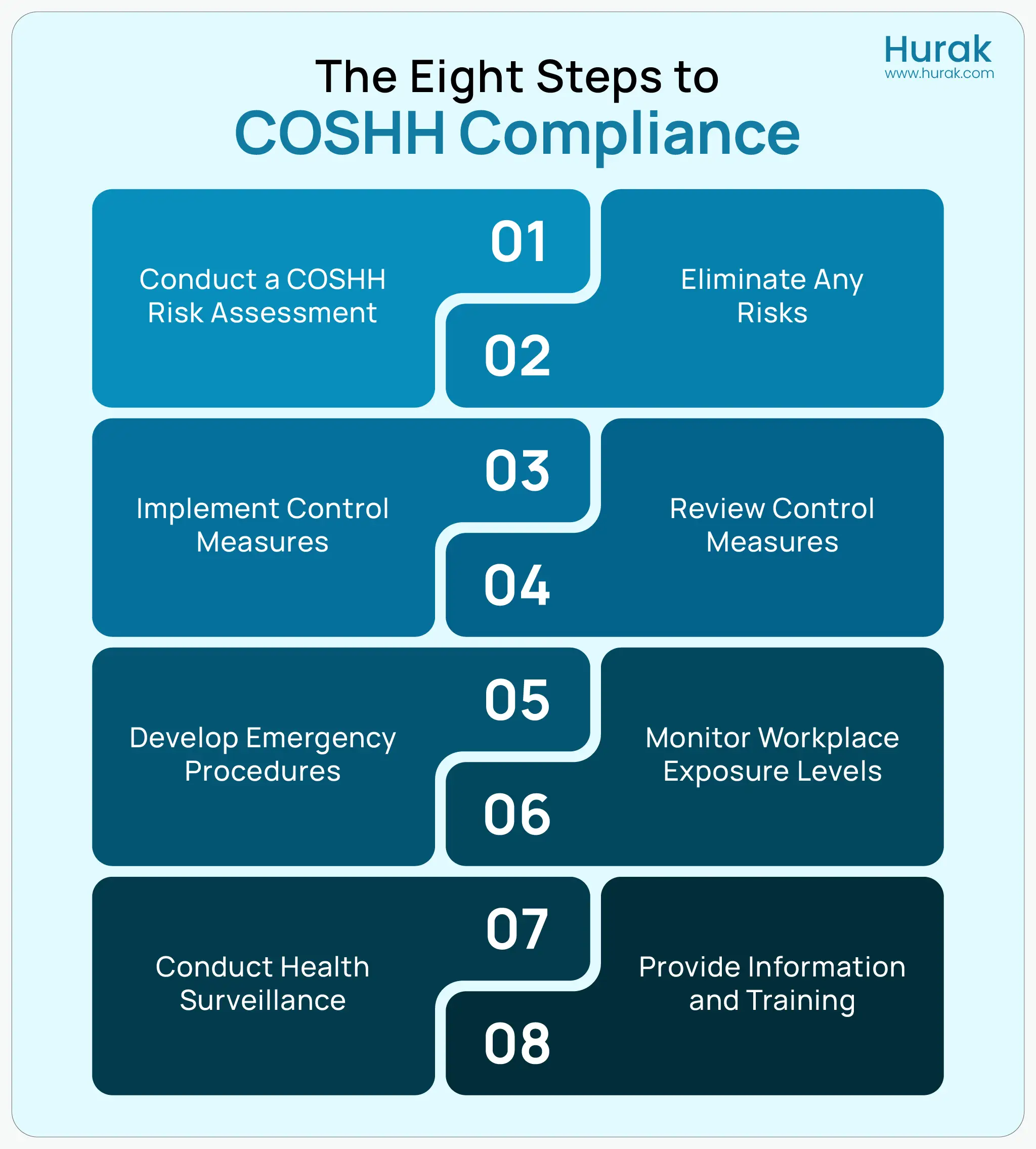

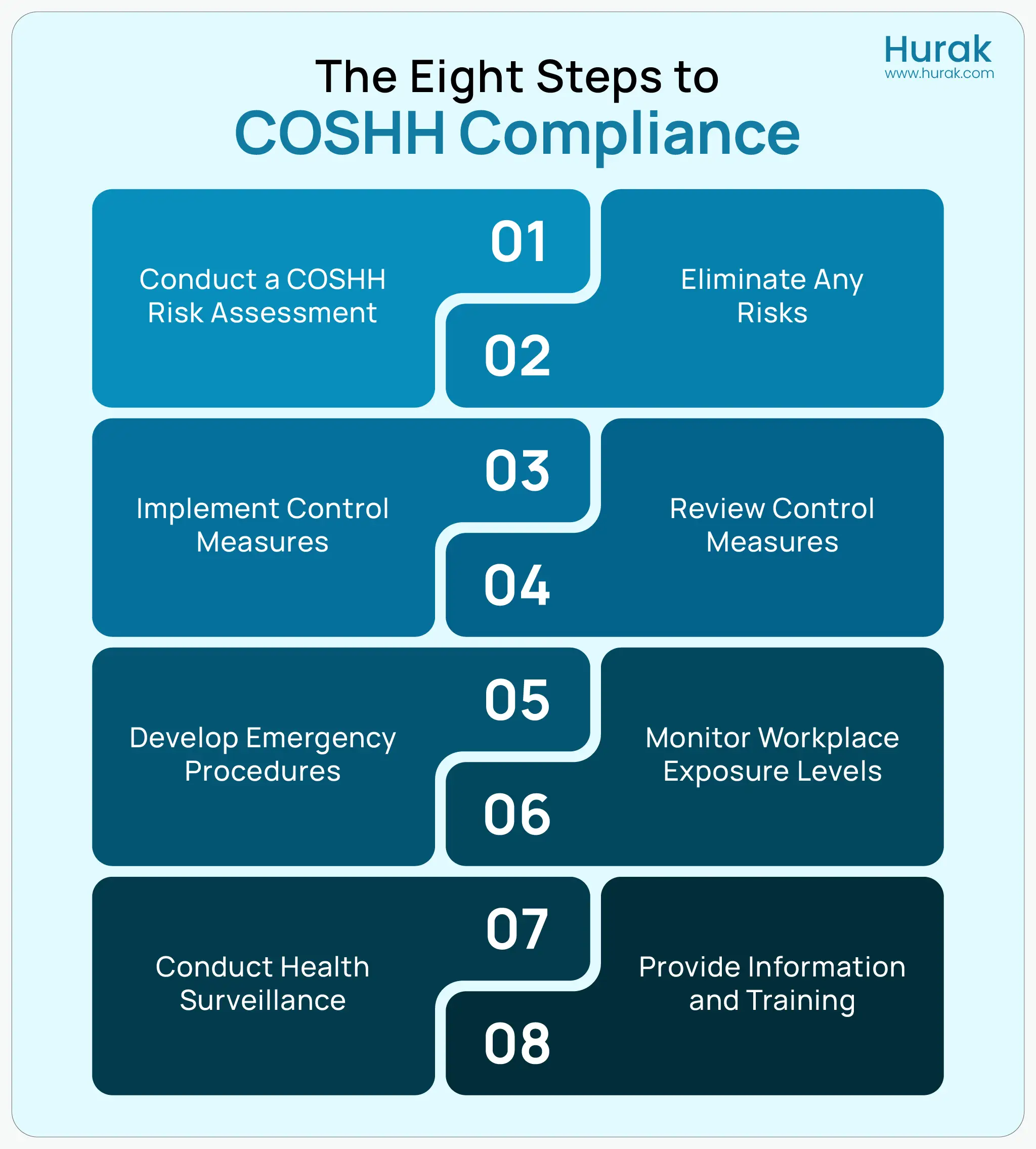

While some organisations summarise six or even five steps, the Health and Safety Executive (HSE) guidance and industry best practice outline eight essential steps. These steps take you from identification to ongoing review, completing a full cycle for safely managing hazardous substances.

8 Steps to Working with COSHH

Here are the eight steps to working with COSHH that every employer, safety officer, and manager should understand.

Step 1: Identify Hazardous Substances in Workplaces

Identifying the chemical, dust, fume, vapour, mist or gas that can potentially cause harm to workers in their workplace should be the first step in determining URL in cocomp.

- Chemicals such as Cleaning Agents, Paints, Solvents, Acids

- Dust, fume, vapour, mist or gas Generated Through the Work Processes

- Biological Agent:s Bacteria and Mould

Create a workplace inventory for all hazardous substances, including by-products (Welding Fume/Wood Dust), as a source of work-related exposure to chemical and biological agents. The inventory must be created

Step 2: Conduct a COSHH Risk Assessment to Determine the Level of Risk of Exposure

After Identifying All Hazardous Substances, the Next Step is to Conduct a COSHH Risk Assessment

Risk Assessment Documentation Should Include:

- Hazardous property of each hazardous substance (Toxic, Corrosive, Irritant or Other)

- Where or How Workers are likely to be Exposed to Hazardous Substances: Inhalation, Skin Contact, or Ingestion

- Who May be Exposed to Hazardous Substances: Workers, Cleaners, Visitors or Contractors

- Duration and Frequency of Potential Worker Exposure to Hazardous Substances

- Existing Controls Including Current Level of Effectiveness

- Further Controls Necessary to Maintain Worker Health and Safety

Risk Assessments Should Follow a Similar Logic as the Following: Identify, Assess, Control, Document and Review the Risk for Its Continuation. Risk Assessments Must be Documented and Remain Available to All Employees Who Require This Information

Step 3: Choosing Controls. COSHH Control Hierarchy

When you have identified a risk, you need to decide how to control it. This can be done using the COSHH Control Hierarchy. This Hierarchy provides you with a structured way to reduce risk using the most effective means first.

- Eliminate: The hazardous material from your workplace (this could mean using a less dangerous cleaning product for your floors)

- Substitute: The hazardous material for something less hazardous (a less dangerous alternative cleaner, for example)

- Engineering Control: (local exhaust ventilation or enclosed systems)

- Administrative Controls: limit the amount of time an employee is exposed to a hazard and/or allow for job rotation so that employees do not have long-term exposure to any one risk. Administrative controls also include providing training to employees about the process of controlling a hazard.

- Personal Protective Equipment(PPE): This should be the last form of protection against a hazard.

Before you rely on PPE alone, you should check the other controls in the hierarchy. For example, you might change to a non-solvent-based cleaning product before you put your employees at risk by using respirators.

Step 4: Implement the controls

Control measures must be implemented correctly in order for them to be effective, for example:-

- Ventilation and/or extraction systems should be installed

- Labelling and storing materials should be done correctly

- Providing and maintaining PPE for all employees should be done

- Safe handling procedures should be in place

- Hazardous areas should be clearly marked.

All employees must be trained on how to use the controls correctly and safely. If you do not train your employees properly, even the best control systems can fail.

Step 5: Ensure Proper Use and Maintenance

Many employers think that installing controls represents complete legal compliance. However, they need to continue to inspect and supervise their controls on an ongoing basis to maintain compliance with the law.

When you are doing ongoing monitoring of the effectiveness of your control systems, you should do so by performing Checklists on a regular basis:

- Inspect Extraction Systems

- Replace Filters and Personal Protection Equipment (PPE)

- Inspect for Leaks, Spills, or Deteriorated Containers

- Ensure Employees are Following Safe Working Procedures

- Keep Records of all Inspections and Maintenance, as they can protect you during Audits or Inspections

Step 6: Monitor Exposure and Conduct Health Surveillance

Employers are required by law to monitor their employees’ exposure to hazardous substances where the Risk Assessment indicates a risk exceeding Workplace Exposure Limits (WELs).

Where there is exposure to the substances listed below, it may also be a requirement to do Health Surveillance of your Employees:

- Isocyanates (which can cause Asthma)

- Lead, Asbestos, or Silica Dust

- Certain Oils or Solvents

You must keep Health Records confidential and up to date; the Monitoring of Employee Exposure Levels not only allows you to comply with the law, it will also allow for early identification of Occupational Illnesses.

Step 7: Prepare for Accidents and Emergencies

Employers are required to have a plan and adequate resources to respond to Emergency Situations, even if they have implemented adequate controls.

To comply with COSHH, you should:

- Provide Spill Kits and Clear Clean-Up Procedures

- Train Staff in First Aid, Emergency Procedures, and Response Procedures

- Post Hazard Signs and Emergency Contact Information, as well as keeping all Safety Data Sheets (SDS’s) readily available in the event of an Employee being Exposed to Hazardous Substances.

Step 8: Review and Update Regularly

The final step is to review your COSHH assessment and control measures regularly, at least annually or whenever there’s a change in:

- Substances used

- Work processes or equipment

- Employee health reports

A review ensures your COSHH compliance remains current and effective. Document every review and improvement made, as this demonstrates due diligence and helps protect your workplace.

Common Mistakes to Avoid

In many cases, businesses are not fully compliant with COSHH due to simple omissions. The number one reason for non-compliance is the lack of regular review of COSHH assessments; therefore, many organisations may not have updated controls, resulting in increased exposure to risk. In addition, many organisations have an over-reliance on PPE (Personal Protective Equipment) rather than eliminating or substituting hazardous substances, and therefore often overlook higher levels of the COSHH hierarchy of control.

Also, many organisations do not provide adequate employee training or supervision, resulting in employees not knowing how to handle substances safely, how to respond correctly to spills/exposure incidents, or how to be aware of their responsibilities to themselves and others. Businesses also often overlook the substances generated by their activities (for example, fumes, vapours, or dust) and focus only on the raw materials they use. Finally, organisations fail to ensure that appropriate health surveillance is conducted for employees exposed to hazardous substances, leading to undetected illness and potential legal consequences.

Beyond Compliance: Why COSHH Matters for Every UK Business

COSHH compliance has been legally mandated; however, compliance also makes good business sense. Providing a safe work environment greatly reduces the chance of an accident and consequently lowers absenteeism as employees take fewer days off due to injury. Supporting an employee’s need for confidence in their protection from harm creates loyalty and desire to produce greater amounts of quality work for the company.

Additionally, effective COSHH management reduces the number of workers’ compensation claims and ultimately lowers business-related insurance premiums, thus saving the employer money over time. Building a strong safety culture does not just improve the employees’ perception of safety; it establishes the company as a reputable business, demonstrating to clients, regulatory agencies, and the employees that the company takes health and safety issues seriously.

Providing COSHH-compliant working conditions is not just an option for all businesses in the UK; it should be viewed as the foundation for all responsible health and safety management for every business in the UK.

COSHH Compliance in Practice: Industry Examples

- You must assess the risks associated with dust from cement, paint and solvents being generated through exposure during construction work.

- Educators and cleaners should be mindful of all cleaning products and disinfectants by ensuring that they are labelled correctly and stored in an appropriate manner.

- Manufacturers should ensure that all welding fume and oil emissions have adequate ventilation and should implement a system of health surveillance to monitor employees’ exposure to them.

You should consider the way in which each sector operates and how best to approach COSHH in your industry. The COSHH framework will always follow the eight steps.

Final Thoughts

There are eight clear steps from identifying hazardous substances to regularly reviewing your controls. Following these steps not only helps your business meet legal requirements but also creates a safer, healthier environment for everyone.

COSHH isn’t just paperwork; it’s about protecting people. And with the right approach, compliance becomes part of your safety culture, not a burden.

Frequently Asked Questions

How many steps are there to COSHH compliance?

There are eight key steps to COSHH compliance in the UK. These steps guide employers from identifying hazardous substances to continuously reviewing safety measures. Following all eight ensures legal compliance and helps protect employees from chemical, biological, or dust-related risks. COSHH compliance isn’t just about completing paperwork; it’s about building a safer workplace and demonstrating due diligence in managing hazardous substances.

What are the eight steps to working with COSHH?

The eight steps to working with COSHH include:

- Identifying hazardous substances

- Assessing the risks

- Applying the hierarchy of control

- Implementing control measures

- Ensuring proper use and maintenance

- Monitoring exposure

- Preparing for emergencies

- Reviewing and updating regularl

How many steps are required by COSHH when thinking about risks?

When thinking about risks, COSHH requires employers to follow five essential steps to effectively identify and control exposure to hazardous substances. These steps are:

- Identify hazards

- Assess the risk

- Implement control measures

- Record finding

- Review regularly

What is the COSHH hierarchy of control?

The COSHH hierarchy of control helps employers reduce or eliminate risks from hazardous substances in order of effectiveness:

- Elimination: Remove the hazardous substance entirely.

- Substitution: Replace it with a safer alternative.

- Engineering controls: Use ventilation or enclosed systems.

- Administrative controls: Rotate tasks, limit exposure time, or provide training.

- Personal Protective Equipment (PPE): The last line of defence.

Employers should always start from the top of the hierarchy, only relying on PPE when other methods aren’t possible.

What should a COSHH risk assessment include?

A COSHH risk assessment should include:

- Identification of hazardous substances

- Who might be exposed and how

- The level and duration of exposure

- Current and proposed control measures

- Health surveillance and emergency procedures

This ensures all potential risks are captured and appropriately managed across UK workplaces.

How many steps are there to a hazardous substances risk assessment?

A hazardous substances risk assessment typically follows five main steps: identify hazards, assess exposure, decide on control measures, implement them, and review regularly. This framework aligns with COSHH requirements and helps employers maintain up-to-date safety controls.