The most common physical activity that is performed in the UK workplaces is manual handling. Whether it’s lifting boxes in a warehouse, repositioning patients in a care home, or moving tools on a construction site, it’s part of everyday working life for many. However, in spite of its widespread use, poor manual handling is a primary cause of workplace injuries, which frequently have prolonged effects.

This guide explains how to apply manual handling techniques properly, how they affect your role and future employability, and how learning them is a smart move not only for beginners but also for experienced professionals.

Understanding Manual Handling

Manual handling is any task that involves the use of physical force to lift, drop, carry, push, pull, or move an object or load. A “load” may be anything: people, boxes, materials, or tools. These tasks are especially widespread in industries such as construction, healthcare, retail, and logistics.

When carried out incorrectly, manual handling can lead to musculoskeletal disorders (MSDs) such as back pain, joint injuries, or long-term mobility problems. The Health and Safety Executive (HSE) reports that manual handling injuries account for more than a third of all work-related injuries in the UK, with most being preventable with the right knowledge and technique

Why Manual Handling Skills Matter

Correct manual handling techniques are important for anyone working in a physically active role. For employees, it prevents injury and maintains productivity. For employers, this often results in fewer absences, lower compensation claims, and smoother day-to-day operations.

In sectors like construction, improper lifting and carrying can lead to more severe incidents, which often connect with broader health and safety risks on construction sites. Understanding how manual handling fits into the broader picture of workplace safety helps you take responsibility for your own health and that of the people around you.

Moreover, having good practice on a regular basis in the handling of manuals will increase your employability. Workers who have basic knowledge about safety expectations and seem responsible in physical work activities tend to be appreciated more by employers.

Core Manual Handling Techniques

Plan the Task

Before you lift anything, stop and assess the situation. Ask yourself:

- Is the load too heavy or awkward to lift alone?

- Is the path clear of obstacles or trip hazards?

- Are there aids, such as trolleys or lifting equipment, that you could use?

This is the time to prevent the risks even before they happen. There are cases where lifting is not required at all.

Position Your Feet for Stability

Safe lifting is based on your position. Keep your feet roughly shoulder-width apart, with one foot slightly forward to maintain balance. Standing with your feet too close together when moving a load reduces your ability to adjust if the load shifts unexpectedly.

Use Your Legs, Not Your Back

The most widespread error in handling involves bending at the waist in order to pick up an object. Instead, bend your knees while keeping your back straight and your head up. As you lift, use the strength of your leg muscles to raise the load. This approach significantly reduces strain on your spine.

Hold the Load Close to Your Body

The further away a load is from your body, the more strain it places on your arms, shoulders, and back. Always hold the load as close as possible, preferably at waist level, and ensure a secure grip before proceeding.

Avoid Twisting Your Body

When you have picked up the load, you must always turn on your feet, not your body. Twisting while lifting is a significant cause of injury. If you need to change direction, stop, pivot your feet, and then continue.

Know When to Ask for Help

Understanding your limits is part of safe practice. In case a load is heavy, bulky or uneven, then seek help or use a handling aid to make sure that you are safe. You should also be aware of how to avoid manual handling risks, such as working in confined spaces or lifting while fatigued.

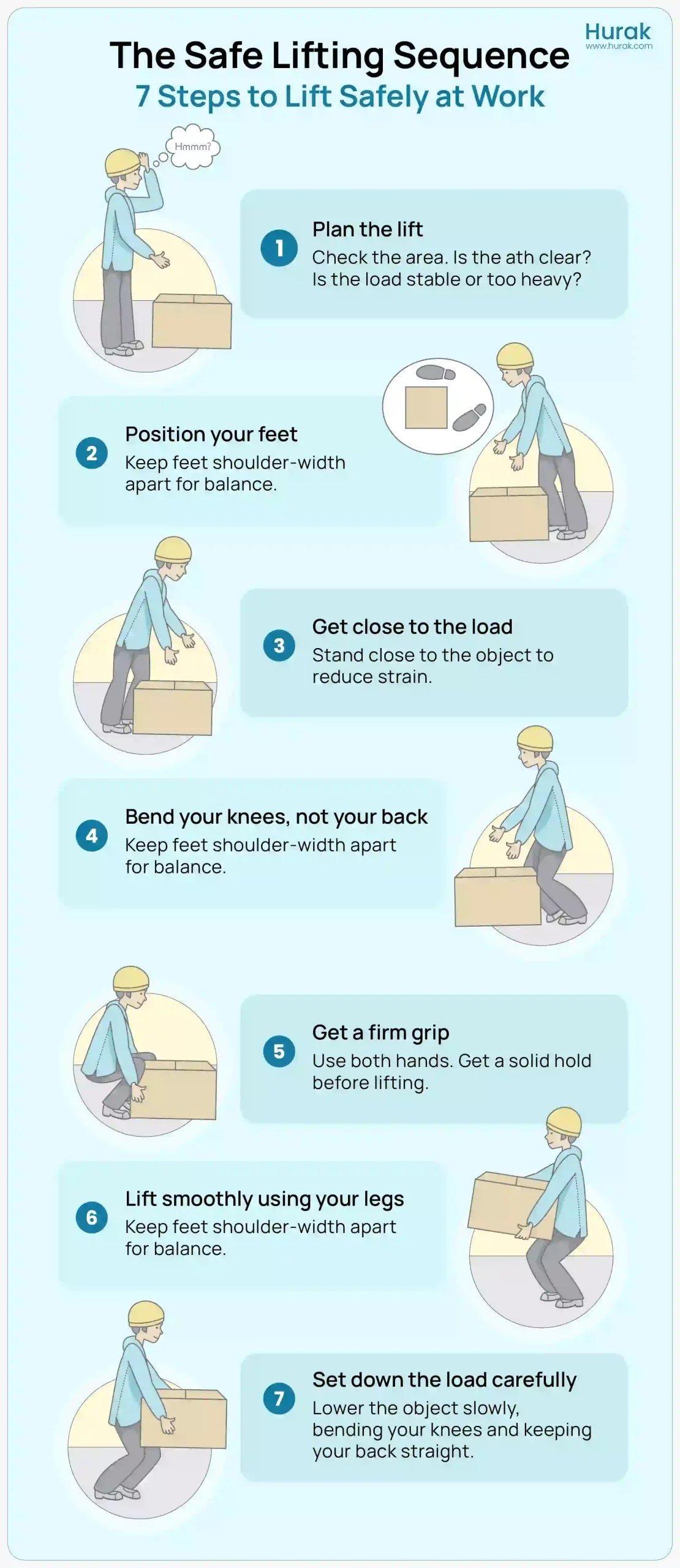

Safe Lifting in Action: A Step-by-Step Example

Assume you are at a warehouse and a package has to be picked up from the floor and placed on a trolley. The way you would do it based on the above principles is as follows:

- Examine the track leading to the trolley, and clear it if necessary.

- Stand with feet shoulder-width apart, one foot slightly forward.

- Sit down, using your knees and hips, not your back.

- Get a firm grip on the package using both hands.

- Lift smoothly using your legs, keeping the box close to your body.

- Move slowly, do not turn or make any sudden movements when carrying the load.

- Lower the box onto the trolley using the same motion in reverse.

This might seem methodical, but once practised, these steps become second nature and significantly reduce the risk of injury.

The Bigger Picture: Creating Safer Work Environments

While individual technique is important, safe manual handling is part of a larger system of health and safety controls. This includes:

- Clear signage and risk assessments

- Proper lighting and ventilation

- Ergonomic equipment and lifting aids

- Training and supervision tailored to job roles

Poor manual handling is often a symptom of broader issues. As highlighted in the consequences of poor health and safety procedures in the workplace, organisations that neglect basic safety often face greater financial, legal, and human costs.

Those in charge of teams or projects are particularly responsible for ensuring these systems are in place. If you’re in or preparing for a leadership role, training like the SSSTS course equip you with the knowledge to enforce safe practices and supervise others effectively.

🦺 For SSSTS (Site Supervisor Safety Training Scheme):

Stepping into a supervisory role?

The SSSTS course equips you with essential knowledge to manage safety on-site, identify manual handling risks, and lead by example. Ideal for individuals seeking to advance in construction supervision.

Training That Makes a Difference

Reading about techniques is helpful, but practical training is where it really clicks. Hurak Manual Handling Course provides a practical introduction to safe practices of handling in different working environments. You will be taught how to assess loads, using techniques and adhere to the health and safety laws.

For those managing sites or larger teams, our SMSTS course builds on this knowledge by teaching how to plan and implement safe working systems, including manual handling processes, across entire projects.

🏗️ For SMSTS (Site Management Safety Training Scheme):

Managing teams and safety at a larger scale?

SMSTS is designed for site managers and senior staff who need a deeper understanding of health and safety responsibilities, including overseeing manual handling practices across complex operations.

Conclusion

Manual handling injuries can be prevented, but only when the proper techniques and awareness are in place. For workers, it’s about taking care of your body and being able to perform your job without unnecessary risk. For employers and supervisors, it’s about leadership, responsibility, and fostering a safe environment for all.

Whether you’re just starting out or working toward a supervisory role, your understanding of manual handling could make a real difference, not only to your safety but to your long-term employability and career satisfaction.

If you’re considering taking on more health and safety responsibilities, understanding the key roles of a safety officer can be your next step. And remember, safety doesn’t end with lifting.

Check out these guides on fire safety at your workplace and practical fire safety tips to complete your knowledge

Frequently Asked Questions

What should always be done prior to lifting a load?

Before lifting any load, always conduct a quick risk assessment to ensure safety. This involves checking the size, weight, and stability of the object, as well as the surrounding space. Is the path clear? Is the load too heavy to lift alone? These steps help prevent unexpected strain or injury. When lifting a load, plan ahead; even a few seconds of preparation can significantly reduce the risk of injury.

Where should you hold and carry your load?

Always keep the load close to your body, ideally at waist height. Holding the object close minimises the leverage force on your back and shoulders, helping you maintain control. Avoid stretching your arms out; this can cause imbalance and place unnecessary strain on your spine. If you’re wondering where you should hold and carry your load, remember: the closer and more centred, the safer.

In general, how should you position your feet when performing a lift?

Place your feet shoulder-width apart to create a strong, stable base. One foot should be slightly in front of the other to help with balance, especially when lifting from the ground. The phrase “feet must be close together when moving a load” is misleading; too narrow a stance actually reduces stability. A broader base gives you greater control during the lift.

What should you not do when lifting a load?

You should not twist your body, bend your back, or jerk the load upwards. These are common mistakes that lead to injuries. Another thing to avoid is lifting something that feels too heavy; always ask for help or use equipment. Also, avoid rushing. What should you not do when lifting a load often comes down to poor posture, poor judgment, or both.

What is the correct technique for lifting?

The correct technique involves the following steps: assess the load, position your feet correctly, bend your knees (not your back), grasp the object securely, lift using your leg muscles, and keep the load close to your body. Avoid twisting while lifting, and instead, pivot your feet to turn. These manual handling principles apply to most lifting tasks, regardless of the setting.

State one tip for safe handling and lifting.

One essential tip is to keep the load close to your body throughout the lift. This simple action reduces pressure on your spine and improves balance. It’s a fundamental part of safe manual handling and is often the difference between a smooth lift and a painful strain.

What is the safe limit of force to push a load?

There isn’t a fixed legal limit, but guidance from the HSE suggests that the maximum recommended force for pushing a load on a flat surface is about 20kg of force for men and 15kg for women under ideal conditions. However, the actual safe limit depends on surface friction, posture, and the height of the load. You should never push or pull a load that feels difficult to control.

When handling an uneven load, what should you do?

You should test the load first and check its centre of gravity. If one side is heavier, try to adjust your grip to keep the load balanced and close to your body. If necessary, reposition the contents or seek assistance. When handling an uneven load, you should avoid sudden movements, as they can lead to instability and injury.

Moving and handling include which of the following actions?

Manual handling encompasses a range of activities, including lifting, carrying, pushing, pulling, lowering, and holding loads using physical effort. It’s not just about lifting; any movement involving force on an object is considered manual handling. Recognising this helps identify more risks, especially when handling repetitive or awkward movements.

Explore Related Courses

Strengthen your knowledge of workplace safety and grow your career with training tailored to your role:

- Manual Handling Training – Understand lifting techniques, reduce injury risk, and stay compliant.

- SSSTS (Site Supervisor Safety Training Scheme) – For those stepping into a site supervision role.

- SMSTS (Site Management Safety Training Scheme) – Designed for site managers to lead safely and legally.

- Health and Safety Awareness (HSA) – A solid starting point for beginners entering the construction or industrial sector.

- Fire Marshal (Fire Warden) Course – Learn fire prevention responsibilities and emergency actions.

- IOSH Working Safely – A short, engaging course ideal for staff across all industries.

- IOSH Managing Safely – For team leaders and managers responsible for health and safety.