In high-risk workplaces, such as construction sites, warehouses, and factories, lifting operations are a daily necessity. However, lifting tasks, whether using cranes, hoists, forklifts, or lifting accessories, carry significant dangers if they aren’t handled correctly. Even a minor oversight can lead to serious injuries or costly damage. To reduce these risks and improve workplace safety across the UK, the government introduced a specific set of rules known as LOLER.

LOLER stands for the Lifting Operations and Lifting Equipment Regulations 1998. These regulations are a legal requirement under the Health and Safety at Work etc. Act 1974, and they apply to any business where lifting operations take place. Understanding LOLER is essential not only for employers but also for site managers, supervisors, health and safety officers, and those looking to enter these roles.

In this guide, we’ll explore what LOLER means, what it covers, and how it influences workplace safety practices. Whether you’re an experienced professional or a beginner just starting in the field, this article will help you grasp the fundamentals of LOLER and why it matters.

What Is LOLER and Why Was It Introduced?

LOLER was introduced to ensure that lifting operations are carried out safely, using suitable equipment and by individuals who are trained to do so. Before LOLER came into effect, there was no unified legal standard for managing lifting equipment and operations in the workplace. Accidents caused by unstable loads, unsuitable equipment, and poorly planned lifts were common and often resulted in serious injuries.

The regulations focus on three main objectives: ensuring that lifting equipment is safe, operations are adequately planned and supervised, and regular inspections are carried out. By meeting these requirements, organisations can significantly reduce the chances of accidents, protect their workers, and avoid legal penalties.

LOLER applies across a wide range of industries, including construction, logistics, healthcare, and manufacturing. It’s particularly relevant in sectors where loads are moved frequently, either manually or mechanically, often under challenging site conditions

Who Is Responsible Under LOLER?

LOLER places legal duties on several roles within a workplace. The employer is ultimately responsible for ensuring that lifting operations meet all safety requirements. However, responsibility doesn’t stop there.

Supervisors and site managers must ensure that lifting activities are appropriately planned, assessed for risk, and carried out under the supervision of a competent person. The law states that a competent person must plan every lifting operation. This individual must have sufficient training, knowledge, and experience to carry out their duties safely.

Operators of lifting equipment must also follow the procedures laid out and report any faults or unsafe conditions. Even equipment owners and hire companies have obligations under LOLER to ensure the equipment they supply is safe and compliant before use.

This shared responsibility model encourages a culture of accountability and promotes safer practices across teams.

📘New to workplace safety or exploring a career shift?

Build a strong foundation in UK health & safety law before you dive into specialisations like LOLER.

Start with the Level 2 Health and Safety in the Workplace Course

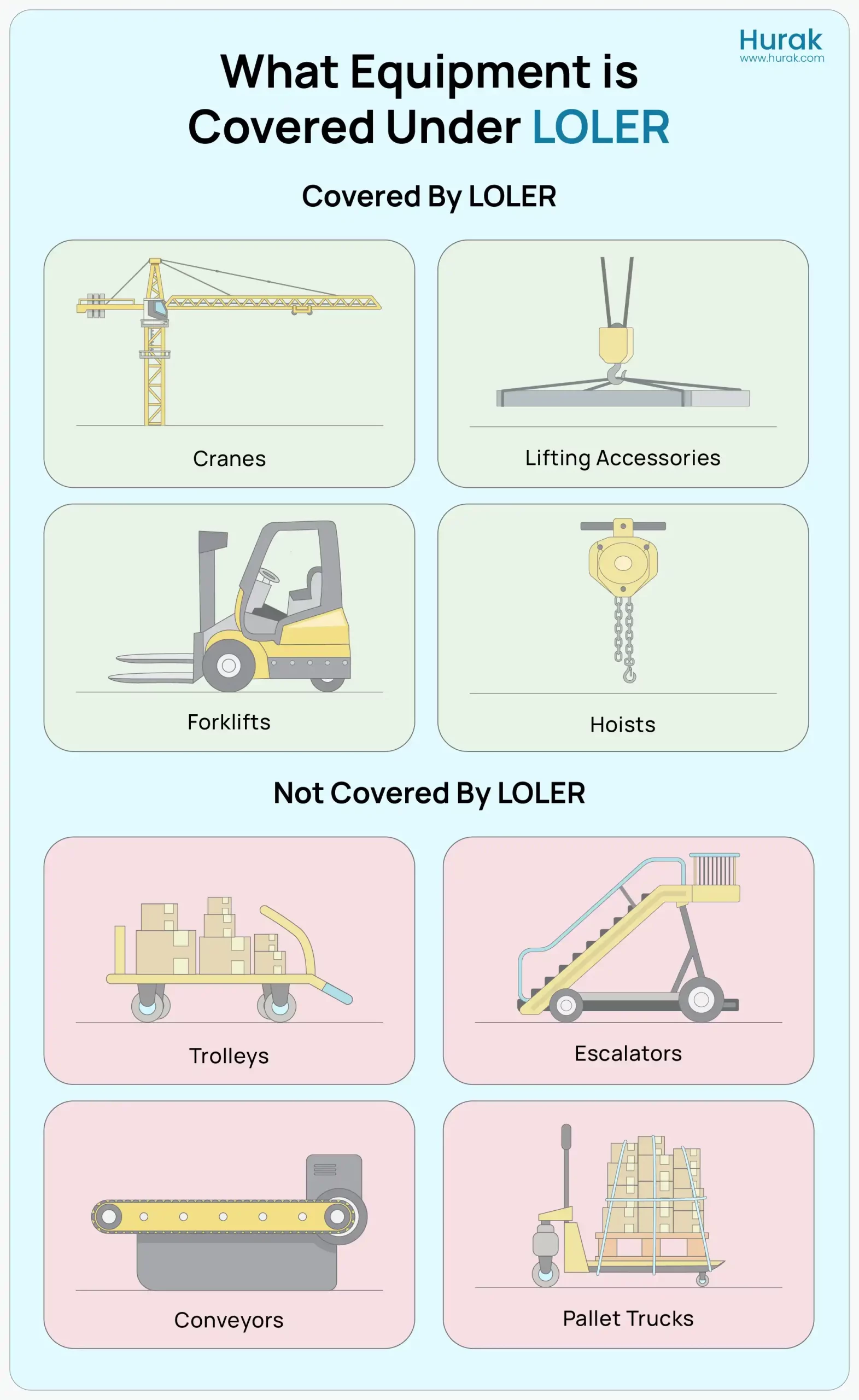

What Equipment Is Covered by LOLER?

LOLER applies to any equipment used to lift or lower a load, and also to the accessories used to attach, support, or anchor the load. Examples include:

- Cranes (mobile, tower, and overhead)

- Forklift trucks and telehandlers

- Passenger and goods lifts

- Chain blocks and hoists

- Mobile Elevating Work Platforms (MEWPs)

- Lifting accessories such as slings, shackles, hooks, eyebolts, and spreader beams

Even lightweight or temporary equipment is covered if it is used to lift loads. It’s important to note that LOLER doesn’t just apply to heavy construction machinery. Any piece of lifting gear, no matter the size, falls under these regulations if it’s used to raise or lower a load from one level to another.

However, LOLER does not cover equipment that moves loads without lifting them, such as trolleys, conveyor belts, pallet trucks (unless used to lift), or escalators. These are generally regulated under PUWER (Provision and Use of Work Equipment Regulations), which focuses on the safe use of all work equipment, not just lifting machinery.

Understanding the distinction between LOLER and PUWER helps businesses ensure full compliance and avoid unnecessary confusion during risk assessments and inspections.

To make things more straightforward, here’s a quick visual guide showing which equipment falls under LOLER and what doesn’t.

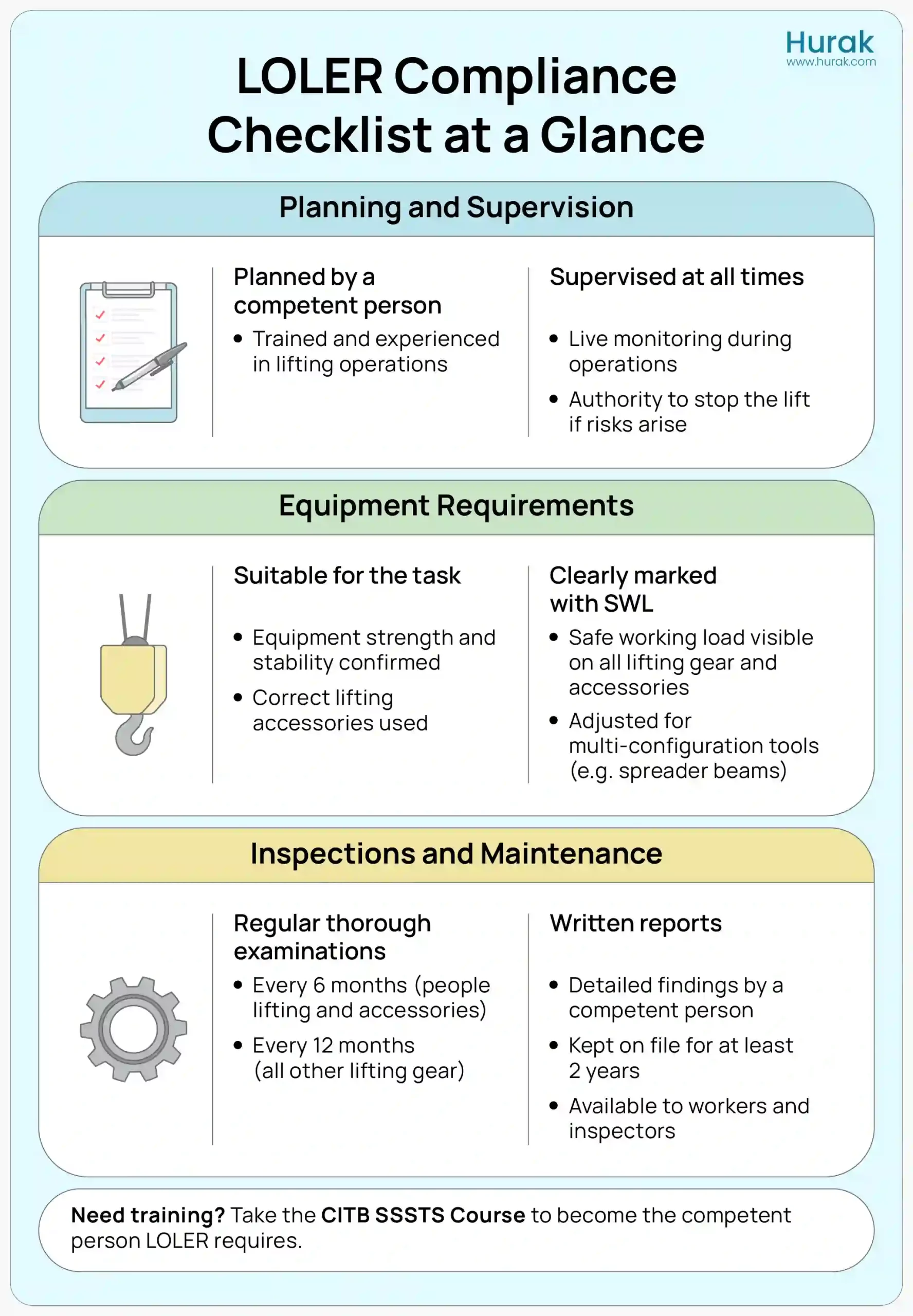

Core Principles of LOLER Compliance

LOLER is built on a few key principles. When applied correctly, they create a safer environment for everyone involved in lifting operations.

Proper Planning and Supervision

Every lifting operation must be planned and supervised by a competent person. This involves evaluating the load, selecting suitable equipment, identifying potential risks, and coordinating the task with team members. On busy sites, especially construction projects with tight schedules, this level of oversight can prevent serious accidents.

Supervision ensures that even well-planned operations are carried out correctly. If something unexpected happens during the lift, a supervisor must be prepared to intervene and make safe decisions in real time.

Equipment Suitability and Safe Working Load (SWL)

LOLER requires that all lifting equipment be suitable for its intended task. This means it must be strong and stable enough to safely carry the load. All equipment should be clearly marked with its Safe Working Load (SWL), the maximum load it can handle under safe conditions.

Using the wrong equipment or exceeding its load limit can result in equipment failure, tipping, or dropped loads. This doesn’t just damage property, it puts lives at risk. That’s why choosing the right equipment is as important as using it correctly.

This principle also applies to lifting accessories. Chains, slings, hooks, and shackles all have their load ratings and must be selected and used based on the job’s requirements.

Inspection and Maintenance Requirements

Regular inspection is another pillar of LOLER compliance. All lifting equipment must be thoroughly examined at legally defined intervals by a competent person. These intervals are:

- Every 6 months, for equipment lifting, people or lifting accessories are required.

- Every 12 months for all other lifting equipment

- After any damage, malfunction, or relocation

Each examination must be followed by a written report. This document should detail the findings, highlight any issues, and confirm whether the equipment is safe to use. Reports must be kept for at least two years and should be readily accessible.

Routine maintenance should also be performed in accordance with the manufacturer’s recommendations. Preventive action is far more effective and far less costly than waiting for something to go wrong.

For organisations, having a documented inspection and maintenance process helps to demonstrate due diligence and prevent the consequences of poor health and safety procedures, including legal penalties and damaged reputation

The Human Side of LOLER: Training and Culture

LOLER compliance isn’t just about equipment; it’s also about people. A well-maintained hoist is still dangerous in the hands of an untrained operator. Similarly, even simple manual handling tasks can lead to injury if not performed with care.

Creating a culture of safety means ensuring that all staff, not just managers, understand the risks associated with lifting and how to mitigate them. Basic training in manual handling, awareness of equipment capabilities, and reporting unsafe practices are all essential habits to develop.

This shared awareness across all roles contributes to a safer, more efficient, and more legally compliant work environment.

Why LOLER Matters for Professionals and Career Seekers

For those already in the workforce, understanding LOLER can help you take on more responsibility and move into leadership roles. Site supervisors, safety officers, and project managers are all expected to understand and apply lifting regulations on the job.

For career seekers, LOLER knowledge adds a layer of credibility and preparedness that employers appreciate. It shows that you understand how safe operations work and that you’re serious about working safely and effectively.

Whether you’re managing operations or just entering the industry, LOLER provides a valuable framework for considering safety, accountability, and competence.

LOLER in Action – A Quick Compliance Checklist

Before we conclude, here’s a visual summary of the key responsibilities and safety checks required under LOLER. This can serve as a practical guide for site supervisors, safety officers, or anyone working around lifting operations.

Final Thoughts

LOLER isn’t just a list of rules; it’s a reflection of the mindset every workplace needs: that safety is a shared priority. From equipment selection to supervision, from maintenance schedules to manual handling practices, LOLER is designed to ensure that lifting operations are carried out without risk to people or property.

For employers, it builds legal compliance and peace of mind. For professionals, it provides a pathway to enhanced leadership. And for beginners, it opens the door to a deeper understanding of workplace safety, one lift at a time.

Frequently Asked Questions

What does LOLER stand for?

LOLER stands for the Lifting Operations and Lifting Equipment Regulations 1998. It is a UK regulation designed to ensure lifting operations in the workplace are carried out safely and responsibly. Introduced under the Health and Safety at Work Act 1974, LOLER helps reduce the risks associated with lifting tasks and places legal responsibilities on those who manage or use lifting equipment.

What is the meaning of LOLER?

The meaning of LOLER lies in its focus on preventing workplace accidents. It requires lifting tasks to be planned, equipment to be suitable and safe, and operations to be supervised by competent individuals. It also mandates routine equipment inspections and detailed record-keeping, all aimed at creating safer working environments.

What equipment is LOLER relevant to?

LOLER applies to any equipment used for lifting or lowering loads. This includes cranes, forklift trucks, passenger and goods lifts, hoists, MEWPs (mobile elevating work platforms), and lifting accessories like chains, hooks, slings, and eyebolts. If the equipment lifts a load from one level to another, LOLER likely applies.

What equipment is not covered by LOLER?

LOLER does not apply to equipment that doesn’t lift loads vertically. Items like trolleys, pallet trucks (when not used to lift), conveyor belts, and escalators are excluded. These are typically covered under PUWER regulations, which address the general safety of workplace equipment.

What is LOLER legislation?

LOLER legislation outlines the legal standards employers must meet when using lifting equipment. It ensures that all lifting operations are safe, well-planned, and supervised. Failure to comply with LOLER can result in enforcement action from the Health and Safety Executive (HSE), including fines or prosecution in severe cases.

What are LOLER regs?

The term “LOLER regs” refers to the specific regulations within the legislation. These include requirements such as using suitable equipment, clearly marking safe working loads, conducting risk assessments, and arranging regular thorough examinations of lifting gear. These regulations apply across various sectors, especially construction and logistics.

How often should lifting equipment be inspected under LOLER?

Inspections must be carried out at regular intervals by a competent person. Equipment lifting people or lifting accessories must be examined every 6 months, while other lifting equipment must be checked at least once every 12 months. Additional inspections are needed if the equipment is damaged, repaired, or moved.

Who is responsible for LOLER compliance?

Responsibility under LOLER is shared. Employers must ensure that lifting tasks meet legal standards, supervisors must plan and oversee them safely, and operators must use equipment properly and report any issues promptly. Equipment owners or hire providers also play a role in ensuring machinery is compliant before it’s used.

Explore Related Courses

Looking to boost your knowledge or take on more responsibility in lifting operations and workplace safety? These popular courses are a smart next step.

- CITB SSSTS Course: Step into a site supervisory role with confidence. Ideal for those planning or overseeing lifting tasks under LOLER.

- CITB SMSTS Course: Aimed at managers handling health & safety on site. Covers legal duties and best practices in depth.

- Manual Handling Awareness Training: Learn how to lift, move, and carry loads safely, an essential skill alongside LOLER compliance.