Manual handling is a common part of work across countless industries. From warehouse staff and healthcare workers to cleaners, retail employees, and construction workers, many people regularly lift, carry, push, or pull items as part of their daily duties. While these tasks may appear straightforward, incorrect handling techniques can lead to painful, sometimes life-changing injuries. Worse still, they’re often overlooked until they force someone to take time off work or even reconsider their career path.

This article breaks down everything you need to know about manual handling injuries, what they are, why they happen, and how you can avoid them. Whether you’re new to the workforce, looking to build your skills, or simply want to stay safe on the job, this guide will help you make more informed, confident decisions.

Understanding Manual Handling Injuries

Manual handling refers to any activity involving the lifting, carrying, lowering, pushing, pulling, or moving of loads by hand or bodily force. It’s one of the most common tasks in the workplace and a leading cause of injury.

The injuries associated with manual handling typically affect the musculoskeletal system, which includes muscles, joints, ligaments, and the spine. According to the Health and Safety Executive (HSE), manual handling injuries account for a significant number of all workplace incidents, particularly in physically intensive jobs.

What makes them particularly concerning is their long-term impact. A strained back or a repetitive shoulder injury might seem manageable at first, but if ignored or repeated, these injuries can become chronic and prevent people from doing their jobs safely or at all

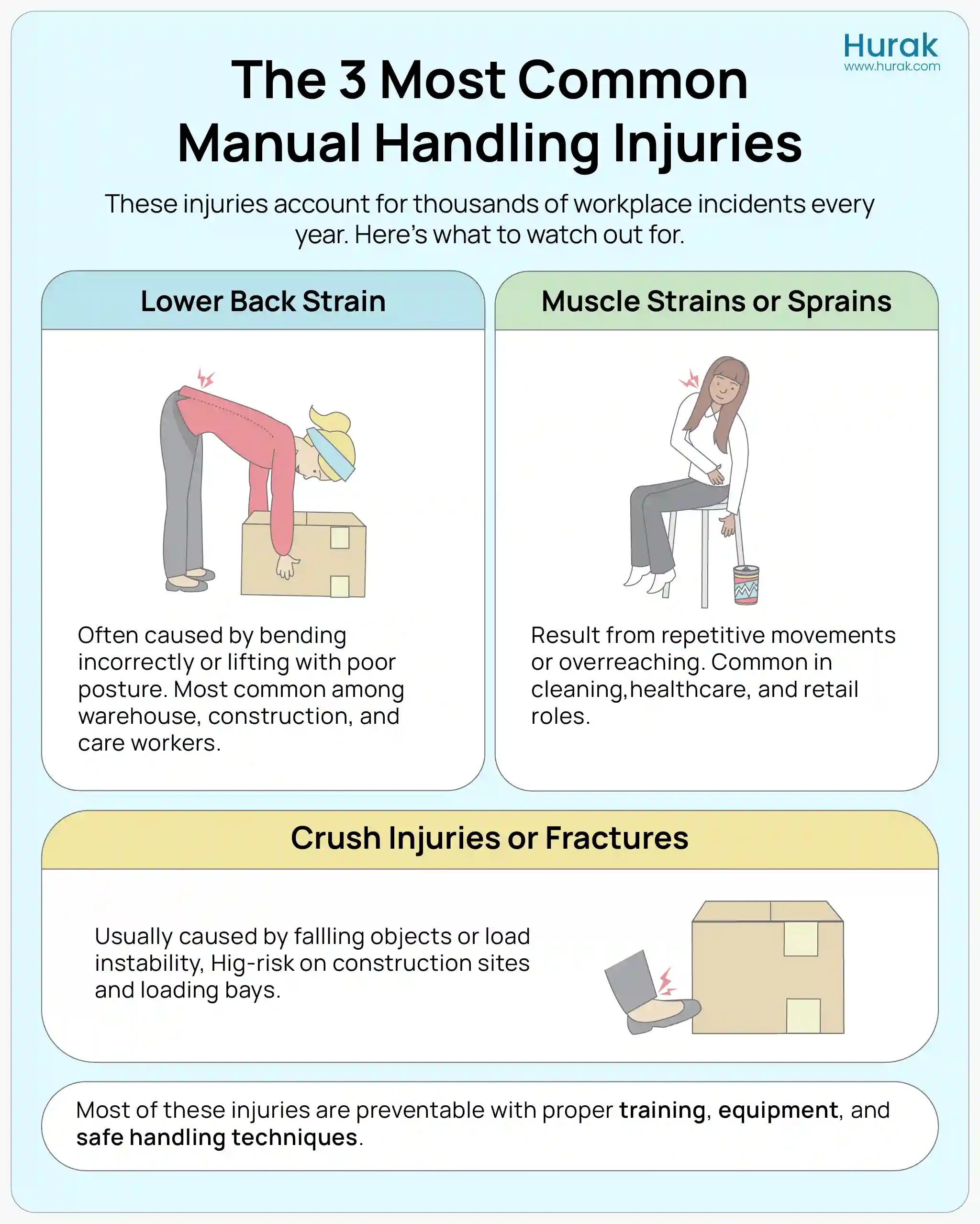

The Most Common Types of Manual Handling Injuries

While there are many ways a person can injure themselves during manual handling tasks, three types of injuries are especially common. Understanding these can help individuals recognise risks early and act before problems worsen

Back Injuries

Back injuries, especially in the lower back, are the most frequently reported. These typically result from bending at the waist, twisting while lifting, or carrying loads that are too heavy or unbalanced. The spine is under immense pressure during improper lifting, and over time, this can lead to serious damage, such as herniated discs, long-term back pain, and restricted mobility.

A logistics worker, for example, might lift dozens of boxes daily. If they don’t use proper form, the strain accumulates, and the injury often strikes suddenly after what seems like a routine movement

Strains and Sprains

Strains (to muscles) and sprains (to ligaments) occur in areas such as the shoulders, arms, wrists, and legs. These often develop over time through repetitive lifting or awkward postures, particularly when tasks involve reaching, twisting, or carrying loads in uncomfortable positions.

Jobs in sectors such as healthcare, where moving people or equipment is part of the role, are particularly prone to these types of injuries. Our article on how to avoid manual handling risks provides a more detailed examination of these issues.

Crush Injuries and Fractures

Although less frequent, crush injuries and broken bones tend to be more severe and are often the result of sudden accidents, such as items falling, fingers getting caught, or heavy equipment tipping over. These are more likely to occur in busy environments, such as construction sites or warehouses, where large objects are frequently moved and stored.

Why These Injuries Keep Occurring

Manual handling injuries are so prevalent because poor habits are easy to fall into, especially when staff are busy, under time pressure, or inadequately trained. Many workers lift loads instinctively, without pausing to assess the situation or plan the safest method of lifting.

Common causes include:

- Poor technique (e.g. bending with the back rather than the knees)

- Overexertion, lifting too much alone instead of asking for help

- Repetitive movements without rest

- Slippery or cluttered workspaces

- Lack of understanding about how injuries build up over time

In some cases, there may also be a cultural problem where people “push through” discomfort or view injuries as part of the job. However, with proper awareness and training, these risks can be significantly reduced.

🛡️ Just getting started with workplace safety?

Our IOSH Working Safely course provides a clear and practical introduction to health and safety principles. It’s perfect for employees in any role who want to work more safely and responsibly.

How to Prevent Manual Handling Injuries

Preventing manual handling injuries begins with education. Workers need to be trained not just on the right techniques but also on how to assess risk and use equipment effectively. Here are the most effective steps individuals and employers can take.

Use Correct Lifting Techniques

Bend at the knees, not the waist. Keep the load close to the body. Avoid twisting. Lift smoothly and avoid sudden movements. While these steps may seem simple, applying them consistently, especially in fast-paced environments, requires attention and habit formation

Assess the Load and Environment

Before handling anything, pause and think:

- Is the item too heavy or awkward to handle?

- Can it be broken into smaller loads?

- Is the path clear, and are there hazards nearby?

This simple risk assessment only takes a few seconds but can prevent serious injury.

Use Equipment and Ask for Help

Manual handling doesn’t mean you have to do everything by hand. Use trolleys, hoists, or other tools whenever available. Don’t hesitate to ask for help with large or heavy items. Many serious injuries happen when someone tries to prove they can do it alone.

Refresh Training Regularly

Manual handling isn’t just about common sense. It involves understanding anatomy, physics, and workplace regulations. Whether you’re new to the job or have years of experience, ongoing training can help correct bad habits and keep you up to date with best practices

The Wider Impact on Career and Safety Culture

For many professionals, physical ability is directly tied to job performance. A single injury can not only interrupt work but also limit future opportunities, especially in industries that rely on strength and stamina. In serious cases, individuals have had to retrain for entirely new careers due to long-term damage from poor manual handling.

That’s why knowledge and prevention aren’t just safety concerns, they’re career strategies. By working safely and demonstrating awareness of risks, individuals also position themselves as responsible, promotable team members. Supervisors and managers, in particular, are expected to lead by example and protect their teams.

For those in or aspiring to these leadership roles, courses such as SSSTS or SMSTS provide a deeper understanding of managing safety on-site, including how to mitigate the risk of manual handling injuries across an entire team.

🎓 Ready to take on more responsibility at work?

The SSSTS course is ideal for team leaders and supervisors. It teaches you how to manage health and safety on-site, prevent injuries such as manual handling accidents, and comply with your legal obligations.

A Safer Future Starts With Awareness

Manual handling injuries are more than an inconvenience; they’re a barrier to long-term success. Whether it’s a strained back or a broken wrist, these injuries can sideline your career, limit opportunities, or cost your employer time and money.

However, the good news is that they’re avoidable. With the right habits, regular training, and a safety-first mindset, you can protect yourself and contribute to creating a safer workplace for others. And if you’re aiming for roles with more responsibility, knowledge of health and safety isn’t just helpful, it’s essential.

To explore additional topics, such as fire prevention, hazard control, or the role of safety officers, browse our expanding health and safety blog

🏗️ Leading a site team? Safety starts with you.

The SMSTS course is designed for site managers who want to lead by example. Gain in-depth knowledge of managing risks, protecting your workforce, and staying compliant with health and safety laws.

Frequently Asked Questions

What are the most common accidents and injuries that can occur when moving and handling people?

When moving and handling people, such as in healthcare or care home settings, the most common injuries include back strains, shoulder injuries, and muscle pulls. These incidents occur when workers attempt to lift or reposition patients without proper assistance or technique. Unlike handling objects, moving people often involves awkward angles and unpredictable shifts in weight. These conditions make it easier to strain muscles or cause joint injuries. To avoid such risks, training in proper people-handling techniques and the use of hoists or slide sheets is essential.

What are the 3 most common types of manual handling injuries?

The three most common manual handling injuries are:

- Lower back injuries are often caused by bending or twisting while lifting.

- Muscle strains and sprains, typically occurring in the shoulders, arms, or wrists, are often caused by repetitive motion or overexertion.

- Crush injuries or fractures may happen when heavy items fall or shift unexpectedly.

These injuries occur across a wide range of jobs and often result from poor lifting techniques, overexertion, or rushing through physical tasks.

What is the most common type of manual handling incident?

The most common type of manual handling incident involves injuries to the lower back, often resulting from lifting heavy or awkward objects incorrectly. These incidents typically stem from bending with the back rather than the knees, twisting during a lift, or carrying loads that are too far from the body. Over time, these practices can lead to chronic conditions that limit mobility and work capacity.

Give two examples of injuries which may be caused by poor manual handling.

Two common injuries caused by poor manual handling are:

- A herniated disc in the lower back can occur from lifting with bad posture or carrying excessive weight.

- Rotator cuff strain in the shoulder often results from reaching overhead or lifting while twisting.

These injuries may start with mild discomfort but can escalate into long-term health problems without proper care or adjustments to working habits.

Which of the following is the most common form of injury resulting from manual handling?

Among the different types of manual handling injuries, musculoskeletal disorders affecting the lower back are the most common. They’re frequently seen in industries such as warehousing, construction, and care services. Repeated strain, awkward postures, and incorrect lifting techniques contribute heavily to this type of injury, making it crucial for both employers and employees to prioritise manual handling safety training.

Explore Related Courses

Whether you’re looking to improve your safety, lead a team, or move into a supervisory role, these courses support your journey:

- Manual Handling Awareness: Understand safe lifting techniques, reduce injury risks, and work more efficiently in physically demanding roles.

- CITB SSSTS (Site Supervisor Safety Training Scheme): For team leaders responsible for safety on-site, including proper manual handling practices.

- CITB SMSTS (Site Management Safety Training Scheme): Designed for site managers looking to manage risks, meet legal duties, and build safer teams.

- SSSTS Refresher: Keep your supervisor certification valid while refreshing your knowledge of site safety and manual handling.

- SMSTS Refresher: Update Your Understanding of Workplace Risks and Continue Leading by Example.

- Health and Safety Awareness Course: A foundational course covering key responsibilities, ideal for new starters across all industries.