Manual handling is part of nearly every workplace, whether it’s lifting boxes in a warehouse, moving patients in healthcare, or carrying equipment on a construction site. That’s where the TILE framework comes in.

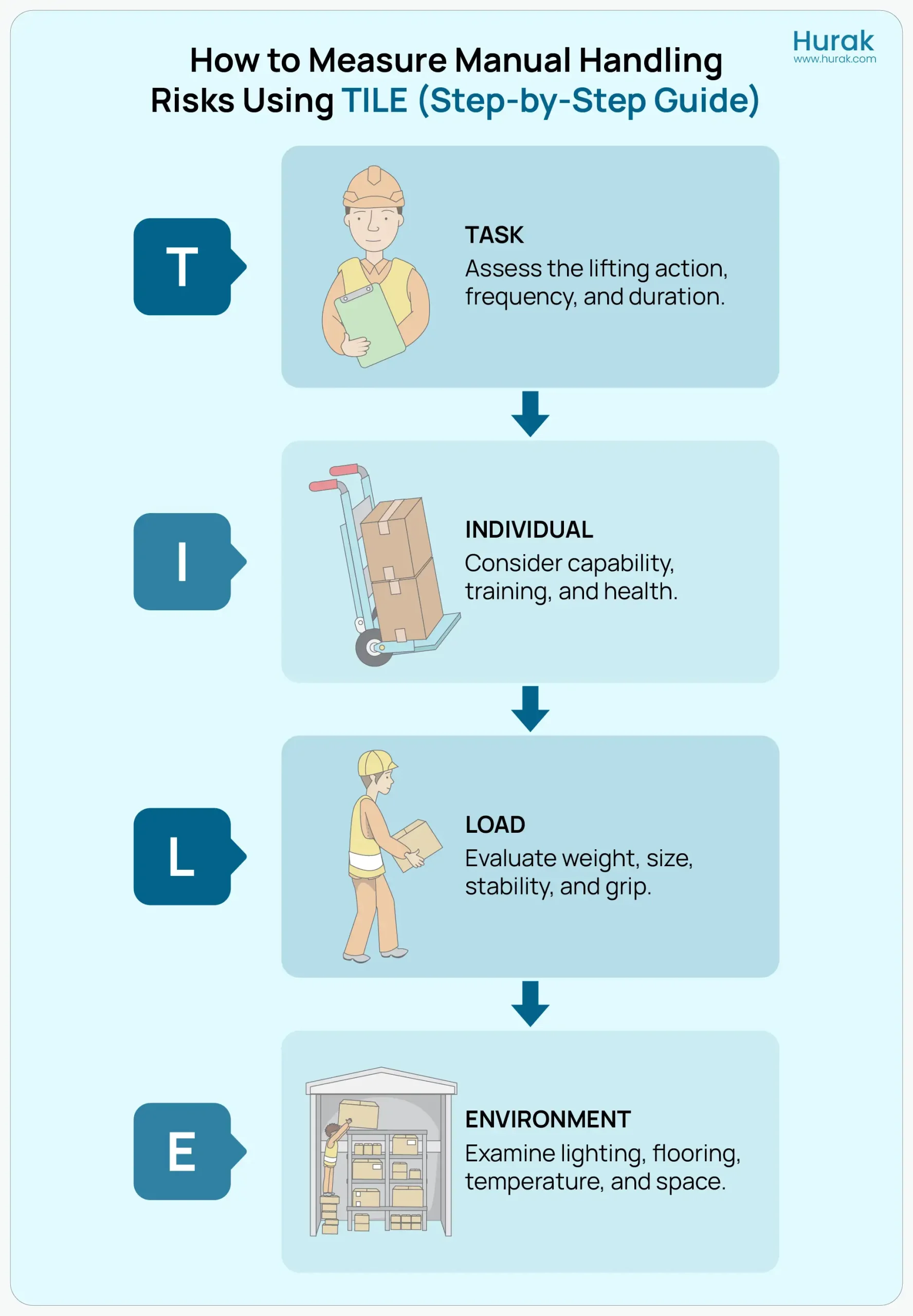

TILE stands for Task, Individual, Load, and Environment, a simple yet powerful method for assessing and minimising manual handling risks. Following this framework helps workers carry out tasks safely while staying compliant with UK Health and Safety Executive (HSE) guidelines.

In this guide, we’ll explain what TILE stands for, how to use it effectively, and how it supports risk assessments. We’ll also explore TILEO, a valid variation of the framework, and show how training can help you apply it in real workplace situations.

Let’s explore how this simple framework can make manual handling safer and more efficient.

What is TILE in Manual Handling?

TILE is a manual handling assessment framework that helps you evaluate risks before performing any lifting or moving task. It stands for:

- T – Task

- I – Individual

- L – Load

- E – Environment

This framework aligns with the HSE’s Manual Handling Operations Regulations 1992, which require employers to assess and mitigate risks associated with manual handling activities.

By thinking through each element of TILE before lifting, for example, before lifting a box, think TILE, workers can avoid unnecessary injuries and ensure that safety measures are in place.

What Does TILE Stand For? (TILE Acronym Explained)

Manual handling is one of the most common causes of workplace injuries, often resulting from incorrect lifting techniques or poorly assessed tasks. To minimise risks and protect employees, the TILE framework is widely used in health and safety training. TILE stands for Task, Individual, Load, and Environment, and provides a structured way to evaluate manual handling techniques before they are carried out. By applying TILE, workers can identify hazards early, reduce strain, and choose the safest approach to completing the job.

T: Task

Before moving any load, examine the task itself. Identify what the activity requires and whether it introduces unnecessary strain.

Consider:

- Repetition: Will the task be repeated multiple times?

- Posture: Does it require bending, reaching, or twisting?

- Distance & frequency: How often and how far must the load be transported?

Real scenario: Warehouse staff frequently rotating their torso while lifting parcels are at high risk of disc injuries; reviewing the task setup might justify using trolleys or repositioning stock.

I: Individual

Before starting any manual handling activity, consider the person performing the task. Different individuals have different levels of strength, experience, and physical ability.

Consider:

- Capability: Is the worker physically able to handle the task?

- Training: Have they received proper manual handling training?

- Health conditions: Do they have injuries, fatigue, or medical concerns that may increase risk?

Real scenario: A new employee with no manual handling training attempts to lift heavy boxes alone and strains their back. Assigning tasks based on ability and ensuring proper training can significantly reduce injury risk.

L: Load

The Load is not just about weight its size, shape, stability, and texture also affect safe handling.

Consider:

- Weight: Is it manageable for one person?

- Size & shape: Can it be gripped securely and comfortably?

- Stability: Is the load evenly balanced or likely to shift?

- Texture: Is it slippery, sharp-edged, or awkward to hold?

Real scenario: A box that appears light may contain loose items that shift suddenly while being lifted, throwing the handler off balance and causing injury. Checking the load first helps identify whether assistance or lifting equipment is required.

E: Environment

The Environment refers to the space and surroundings where manual handling takes place. A safe load can still be dangerous if the environment is unsafe.

Consider:

- Floor conditions: Are surfaces uneven, wet, or slippery?

- Lighting: Is visibility clear enough to move safely?

- Space: Is there enough room to lift and manoeuvre the load?

- Obstacles & distractions: Are walkways clear and noise levels manageable?

Real scenario: Moving a heavy trolley through a cluttered and dimly lit corridor increases the chance of slips, trips, and collisions. Clearing pathways and improving lighting before handling prevents avoidable accidents.

Understanding the TILE Framework (Task, Individual, Load, Environment)

The TILE framework is a structured method for assessing manual handling risks. It helps identify hazards before work begins and ensures each element of the task has been reviewed. Why it matters

- Prevents injuries: Reduces the risk of back strain and musculoskeletal disorders.

- Ensures compliance: Meets HSE manual handling legal requirements.

- Improves productivity: Workers can handle loads more confidently and efficiently.

Pro Tip: The TILE framework works best when it’s reviewed regularly and applied to every new task, not just heavy lifting.

What Is TILEO? (Extra ‘O’ Explained)

You may also come across the extended version: TILEO. Here, the “O” stands for Other factors, any additional risks not covered by the main four categories.

“O”: Other Factors

- Equipment condition (e.g., broken trolleys or faulty straps)

- Team coordination when lifting together

- Time pressure or tight deadlines

- Availability and proper use of PPE

Comparison Table:

| Framework |

Stands For |

Focus |

| TILE |

Task, Individual, Load, Environment |

Core manual handling assessment |

| TILEO |

Task, Individual, Load, Environment, Other factors |

Adds wider situational awareness |

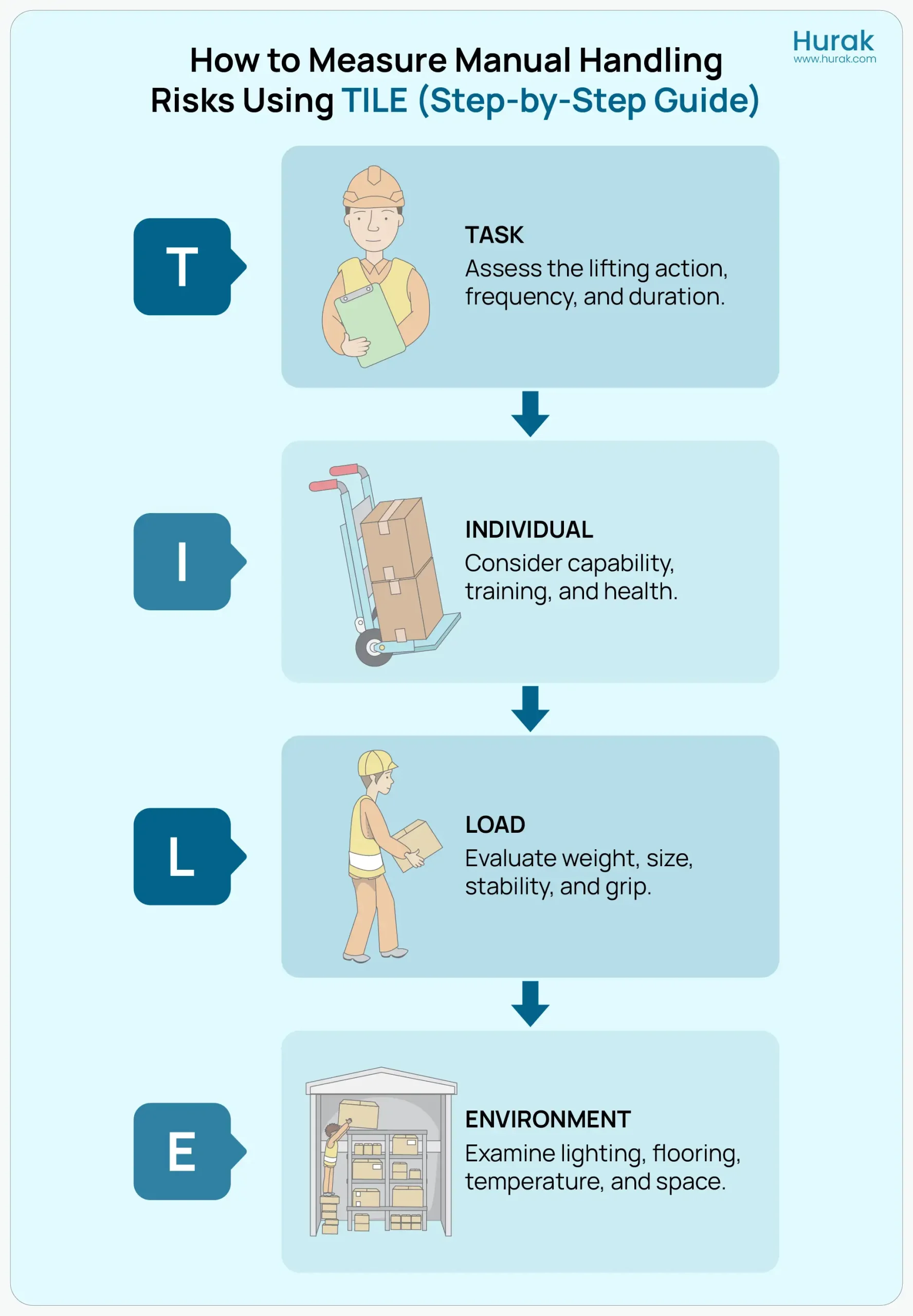

How To Apply the TILE in Manual Handling Step-by-Step

Applying TILE effectively involves a step-by-step process that anyone in the workplace can follow.

Step 1: Understand the Task

Identify what needs to be done, including lifting, pushing, or carrying, and how often it is required. Avoid awkward movements or long carrying distances.

Step 2: Evaluate the Individual

Verify that the worker is fit and adequately trained for the job. Rotate tasks if necessary to prevent fatigue.

Step 3: Examine the Load

Inspect the load’s size, shape, and stability. Test its weight before fully lifting.

Step 4: Inspect the Environment

Look for obstructions, slippery floors, or poor lighting. Adjust the layout if needed.

Step 5: Review and Record

Record your findings as part of your manual handling risk assessment. Documentation aids in compliance and facilitates future training. Encourage supervisors to involve workers in the TILE process. This builds safety awareness across teams.

TILE and Risk Assessment: Why It Matters for Workplace Safety

TILE is not just a checklist; it’s a vital component of a comprehensive workplace risk assessment.

By integrating TILE into your risk assessment:

- You ensure every factor influencing safety is reviewed.

- You meet HSE’s legal expectations.

- You create a safer, more proactive culture.

Common injuries prevented through TILE include:

- Back pain

- Muscle strains

- Shoulder and knee injuries

Example: A worker who lifts a heavy box without assessing the Load and Environment may twist their back. Using TILE, they’d recognise the uneven floor and ask for help preventing injury.

TILE vs LITE: What’s the Difference?

Another variation you may come across in manual handling is LITE, which stands for Load, Individual, Task, Environment. While both frameworks share the same core components, the order of assessment changes slightly, and that difference can influence how you approach risk evaluation.

Both TILE and LITE aim to help workers think systematically before carrying out any lifting, pushing, or pulling task. However, understanding their distinctions can help you choose the method that fits your workplace routine best.

TILE (Task, Individual, Load, Environment)

The TILE approach begins by assessing the Task first. This method is often used when the nature of the job or process is complex, for example, when multiple manual handling activities are involved or when a sequence of movements must be considered.

By focusing on the task, you identify potential risks early, such as repetitive actions, awkward postures, or long carrying distances. It’s particularly effective in industries like construction, logistics, and manufacturing, where each task can differ greatly.

LITE (Load, Individual, Task, Environment)

In contrast, the LITE method starts with loading the object or item being handled. This approach is practical when the object itself poses the primary risk, such as when its size, weight, or shape makes it difficult to move safely. By examining the load first, workers quickly assess whether mechanical aids, team lifts, or weight checks are needed before moving further into the assessment.

Key Difference

| Framework |

Full Form |

Starting Focus |

Best Used For |

| TILE |

Task, Individual, Load, Environment |

Starts with assessing the task |

When work involves multiple or complex handling steps |

| LITE |

Load, Individual, Task, Environment |

Begins with assessing the load |

When the object’s weight or design poses the main challenge |

Which One Should You Use?

There’s no strict rule about which framework is better; both support safe and compliant manual handling.

Many workplaces choose TILE because it encourages a broader view of the whole operation, helping identify both human and environmental factors. However, LITE can be more intuitive for quick assessments, especially when dealing with varied or unpredictable loads.

Practical Examples of TILE in the Workplace

Warehouse & Logistics: Workers use TILE to assess the Task (lifting boxes repeatedly), Load (checking weight and stability), and Environment (clear aisles). This reduces the risk of back injuries and dropped loads.

Healthcare: Before moving a patient, staff evaluate the Individual (capability), Load (patient weight), and Environment (bed height, space). TILE ensures the safety of both patients and staff.

Construction: Handling materials on uneven surfaces becomes safer when TILE is applied to assess task type, surface stability, and weather conditions.

Office Settings: Even in low-risk environments, TILE helps when rearranging furniture or moving printers, ensuring workers bend correctly and clear pathways.

Common Mistakes to Avoid When Using TILE

- Ignoring individual limitations or overestimating ability.

- Rushing through assessments to save time.

- Overlooking environmental hazards like poor lighting.

- Assuming TILE only applies to heavy lifting tasks.

- Failing to revisit TILE regularly as tasks change.

By avoiding these errors, you create a safer, more consistent manual handling culture.

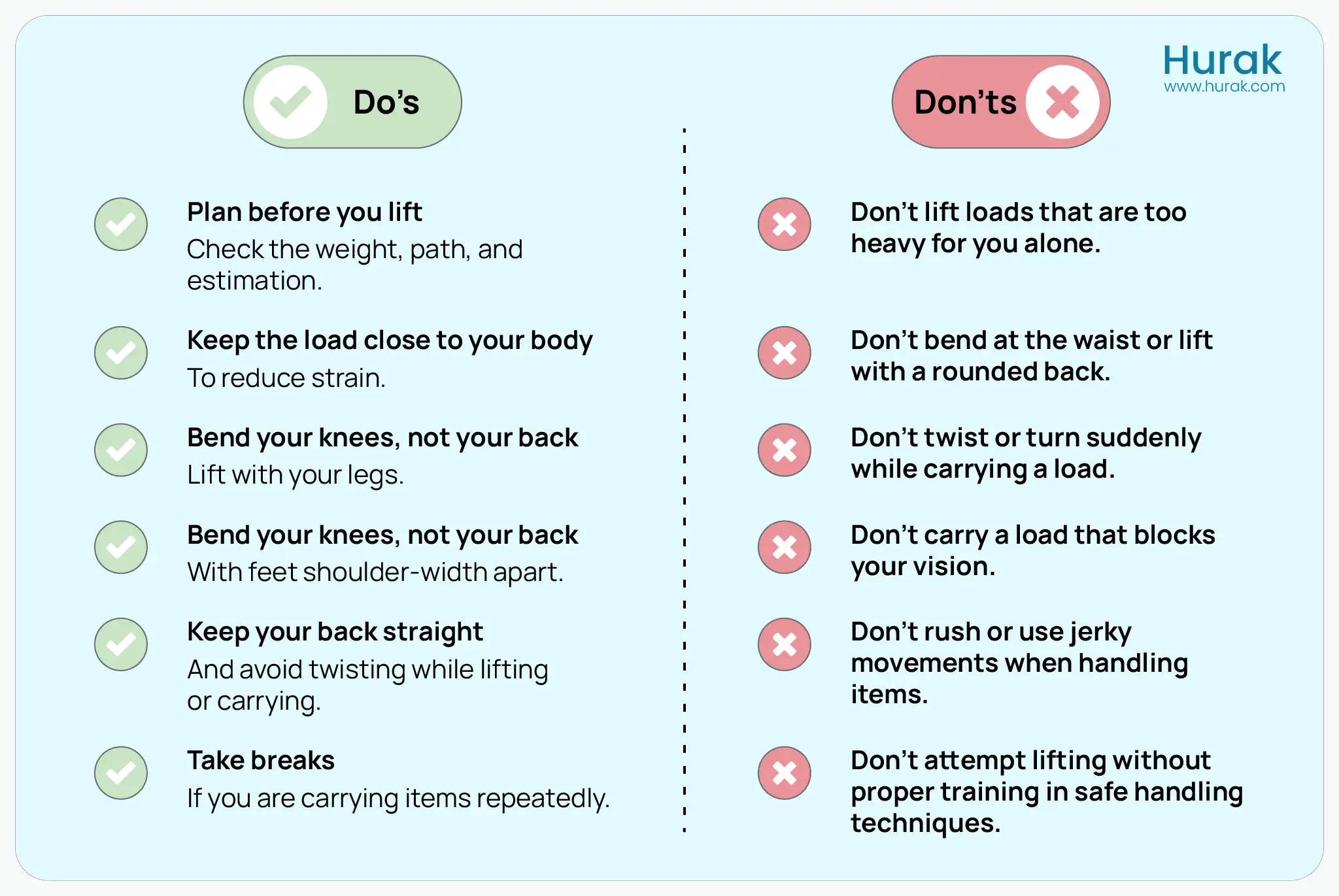

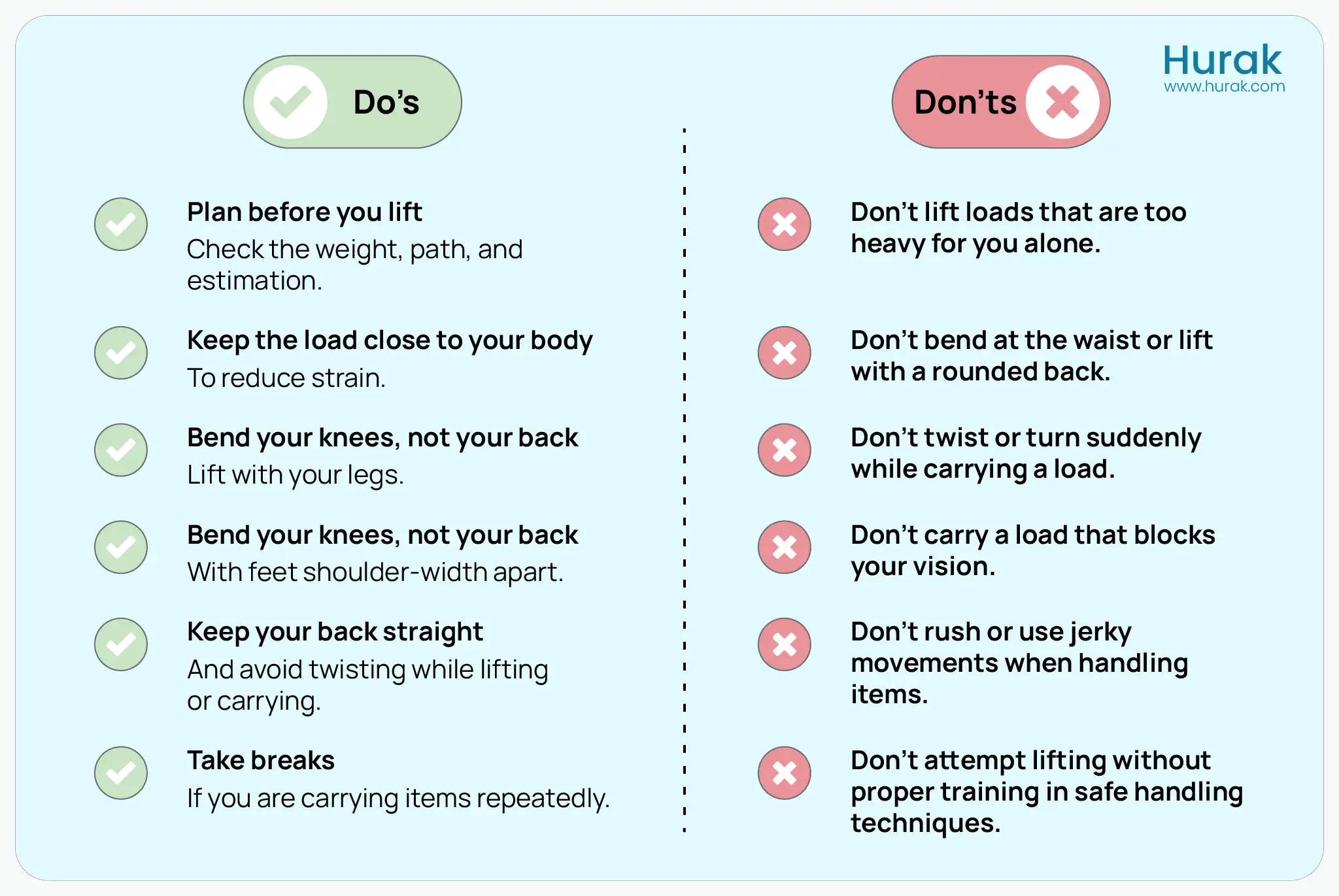

TILE Do’s and Don’ts

To reinforce correct application and make these points easier to remember, the infographic below highlights the key dos and don’ts of using the TILE framework in everyday workplace scenarios.

How Manual Handling Training Reinforces the TILE Framework

Manual handling training plays a crucial role in helping workers understand how to assess risks and apply the TILE framework correctly in real-world situations. Through structured training programmes such as Hurak’s Health & Safety courses, employees gain practical experience in safe lifting and moving techniques, learn how to carry out a TILE-based risk assessment, and understand their legal responsibilities under UK workplace safety laws.

Training also builds confidence, ensuring workers know how to recognise hazards early, choose the safest lifting method, and decide when mechanical aids or additional support are needed. By strengthening knowledge and improving decision-making, manual handling training transforms TILE from a theoretical concept into a daily workplace habit.

To build confidence in using the TILE framework and meet workplace legal requirements, enrolling in an accredited training course can provide the practical skills needed for safer lifting.

Explore our other Health & Safety Course

Conclusion

To summarise, TILE Task, Individual, Load, Environment is a simple yet effective framework for safe manual handling. It helps workers assess risks, improve efficiency, and stay compliant with safety regulations.

By applying TILE consistently and pairing it with proper training, workplaces can significantly reduce the incidence of manual handling injuries.

FAQs about the TILE Framework

What does TILE stand for in manual handling?

TILE stands for Task, Individual, Load, and Environment, a framework used to assess manual handling risks.

What’s the difference between TILE and TILEO?

TILEO adds an extra “O” for Other factors, such as equipment, teamwork, or time pressure.

Is TILE required by law?

While not legally required by name, TILE supports compliance with HSE’s Manual Handling Operations Regulations 1992.

How often should TILE risk assessments be reviewed?

Regularly, especially when new tasks, staff, or conditions are introduced.

Can TILE be applied outside manual handling tasks?

Yes, TILE principles can improve ergonomics and reduce risks in other physical or repetitive tasks