According to HSE data, falls from height are one of the largest causes of occupational accidents within the UK. Various examples can be found with regard to individuals who have fallen from elevated locations. A painter using a scaffold, a maintenance engineer replacing light bulbs, and a warehouse operative stacking goods are just a few examples of employees who are all subject to injury if the proper methods of preventing falls are not followed.

To combat the threats associated with falling from heights, the Working at Height Regulations 2005 were enacted. This legislation was created to prevent loss of life and/or serious injury from falls by ensuring that all activities above ground are properly planned, supervised, and executed.Working at Height Regulations UK apply to all industries; therefore, if your employment includes any type of activity involving a potential fall risk, you are required to comply with the regulations. Construction tends to be a very high-risk area that often requires an extensive amount of regulation due to the multitude of different hazards that can occur on-site. Other dangers that every workplace must manage can also be identified. Explore the top health and safety risks every site should manage.

What Are the Working at Height Regulations 2005?

The Work at Height Regulations 2005 are part of the broader requirements of the Health and Safety at Work Act 1974 regarding the creation of a safe workplace for all employees. The Regulations came into force on 6 April 2005 and provide detailed instructions for planning, organising and carrying out tasks that are carried out at height.

The main purpose of the Work at Height Regulations is to prevent or reduce injury to workers by ensuring that any work done at height:

- Is properly managed

- Is Done Only by Competent Individuals

- Uses Appropriate Equipment

It is important to remember that there is no minimum height for the application of the Work at Height Regulations. Even a fall from a step ladder can lead to serious injuries, so proper safety precautions should be taken for any work done at height.

Key Duties Under the Law

The Work at Height Regulations outline specific responsibilities for both employers and employees.

- Employer and Duty Holders

It is the responsibility of employers and duty holders to properly plan and supervise all work being performed at height. Prior to the beginning of any work, employers and duty holders should conduct a comprehensive risk assessment, provide suitable and properly maintained equipment, and appropriately train and ensure that their employees are competent to perform their assigned duties safely.

- Employees

Employees also carry legal obligations under these regulations. They should adhere to any safety procedures provided by their employer and adequately trained in them, utilise any personal protective equipment (PPE) provided by their employer correctly and safely, and report any hazards, defects or unsafe working conditions immediately.

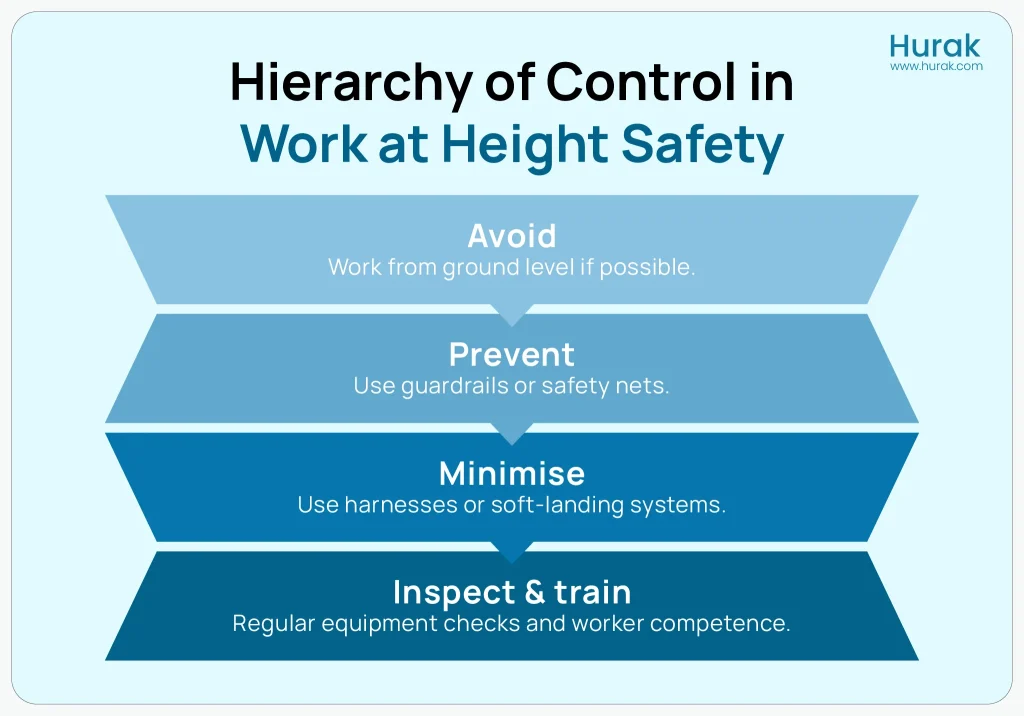

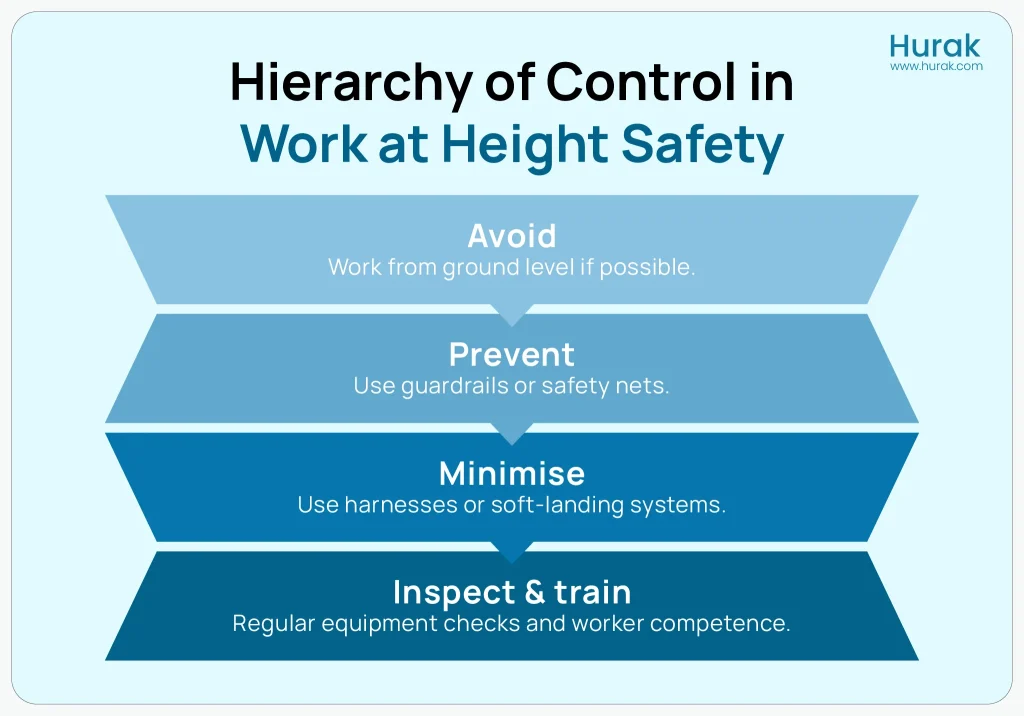

- The Hierarchy of Control

The Enforcement Priority of Controls is one of the central regulations, and it operates off of a fundamental concept of safety: Avoid working at heights whenever possible, If this is not possible, prevent anything from falling by using an elimination method such as using guards or safe falls. If part of the fall risk remains, reduce the distance of the fall with the use of safe landing method equipment such as soft landing systems and/or harness systems.

Suitable Access Equipment and Legal Requirements

What employers need to do, as outlined by the Work at Height Regulations 2005, specifically Regulation 7, is ensure they select and utilise appropriate access equipment that either prevents or minimises the potential for workers to fall from height. The correct choice of equipment is vital to ensuring a workplace is safe, because selecting or using the wrong piece of access equipment may result in serious injury and/or death.

Employers have many types of access equipment available to them when undertaking work at height. Among other things, these include:

- Step ladders and ladders

- Scaffold and Mobile Scaffolding Towers

- Mobile Elevating Work Platforms (MEWPs)

- Safety Harnesses with Appropriate Anchor Systems

All access equipment utilised by Employers should be regularly inspected, maintained, and used only by Competent and Trained personnel. Any access equipment found to be faulty and/or unsafe should be immediately reported, taken out of service, and repaired or replaced as appropriate.

By meeting these legal obligations, employers can not only ensure compliance with the law but also protect their employees from preventable falls and injuries by fostering safe, responsible work environments.

Training and Competence: Why It’s Essential

The Work at Height Regulations 2005 in the Constitution of the United Kingdom require that all individuals participating in work at height activities possess the demonstrated competence and training necessary for the performance of such work safely.

Competence should not be narrowly defined as having completed a training course; one must recognise the possible hazards associated with working at height, the ability to make appropriate safety decisions, and understand their role in protecting themselves and others.

In addition, a competent worker should be familiar with what constitutes a training program and what it should provide.

Some of the topics that may be part of a training program for people working at height are:

- Recognising and evaluating risks associated with working at height

- Selecting & Inspecting Access Equipment

- Safe Use of Ladders and Harnesses

- Emergency & Rescue Procedures

- Understanding Inspection & Maintenance Records

In addition to the need for proper training prior to beginning work at height, employers have a legal obligation to provide periodic refresher training which maintains competency and thus promotes a safer working environment and continued compliance with the regulations.

Common Mistakes to Avoid When Working at Height

All experienced workers can make avoidable mistakes. Here are a few examples of common and dangerous errors made by experienced workers:

- Failing to complete or rushing through a Risk Assessment before beginning a project.

- Using ladders that are damaged/unstable, or not suitable for the job at hand.

- Not taking into consideration the weather or ground conditions prior to starting a task.

- Not using Personal Protective Equipment (PPE) in the correct way (for example, not wearing a harness properly) or not using appropriate PPE at all.

- Failure to provide adequate supervision or communication for the task at hand.

A proactive approach to planning each task, inspecting equipment and keeping training current will help to avoid most falls. The reality is that most accidents occur due to workers not recognising obvious hazards such as uneven surfaces or poor housekeeping, , resulting in minor slips, trips and then ultimately very serious injuries when working at height.

Enforcement, Penalties, and Case Studies

The Health and Safety Executive (HSE) enforces the Work at Height Regulations 2005 and inspectors may issue three types of notice to employers who do not comply with the regulations:

- Improvement Notices, which require unsafe work practices to be rectified,

- Prohibition Notices to stop an employer from continuing unsafe work practices immediately,

- Fines and prosecutions for serious or repeated cases of non-compliance.

A roofing contractor based in the UK was fined more than £50,000 for not using safe working practices while repairing roofs, based on the need for guardrails and adequate supervision. This is proof that non-compliance can be very expensive.

Conclusion

The Work at Height Regulations 2005 are in place to protect everyone who works above ground level. By following the hierarchy of control, utilising the appropriate access equipment, and ensuring your team is properly trained, you can prevent accidents before they occur.

Don’t wait for an inspection or a warning to take action. Compliance starts with awareness and training.

FAQs on Working at Height Regulations

What date did the current Working at Height Regulation come into force?

The current working at height regulation come into force on April 6 2005. They were introduced to reduce the risk of injury and fatalities caused by falls from height in the workplace.

What is the main legislation that covers work at height?

The Work at Height Regulations 2005, made under the Health and Safety at Work etc. Act 1974.

Who do these regulations apply to?

All employers, contractors, self-employed individuals, and anyone who controls or organises work at height.

Is there a minimum height for these regulations to apply?

No. The law applies whenever there’s a risk of injury from a fall, regardless of height.

What equipment is covered?

Ladders, scaffolding, MEWPs, roof access systems, harnesses, and fall arrest gear.

Explore Related Courses

Whether you’re looking to improve your safety, lead a team, or move into a supervisory role, these courses support your journey:

- Manual Handling Awareness: Understand safe lifting techniques, reduce injury risks, and work more efficiently in physically demanding roles.

- CITB SSSTS (Site Supervisor Safety Training Scheme): For team leaders responsible for safety on-site, including proper manual handling practices.

- CITB SMSTS (Site Management Safety Training Scheme): Designed for site managers looking to manage risks, meet legal duties, and build safer teams.

- SSSTS Refresher: Keep your supervisor certification valid while refreshing your knowledge of site safety and manual handling.

- SMSTS Refresher: Update Your Understanding of Workplace Risks and Continue Leading by Example.

- Health and Safety Awareness Course: A foundational course covering key responsibilities, ideal for new starters across all industries.

- Working at Height Training: This course teaches workers how to safely plan, perform, and supervise tasks carried out above ground level. It covers essential topics like risk assessment, safe equipment use, and compliance with the Work at Height Regulations 2005.

- Safety Harness Training: This course provides practical knowledge on the correct selection, inspection, and use of safety harnesses and fall arrest systems. Learners gain hands-on skills to prevent falls and ensure compliance with UK height safety standards.