Whether in construction, agriculture, or utilities, many workers face the hidden dangers of confined spaces daily. A confined space isn’t just defined by its size; it’s the potential hazards inside, such as poisonous gases, lack of oxygen, or restricted exits, that make it so dangerous. These risks have led to the introduction of strict legislation under the Confined Spaces Regulations 1997, designed to protect workers and prevent accidents.

This article provides a clear overview of the risks associated with working in confined spaces, the practical safety measures that can save lives, and the legal responsibilities that both employers and workers must understand.

What is a Confined Space?

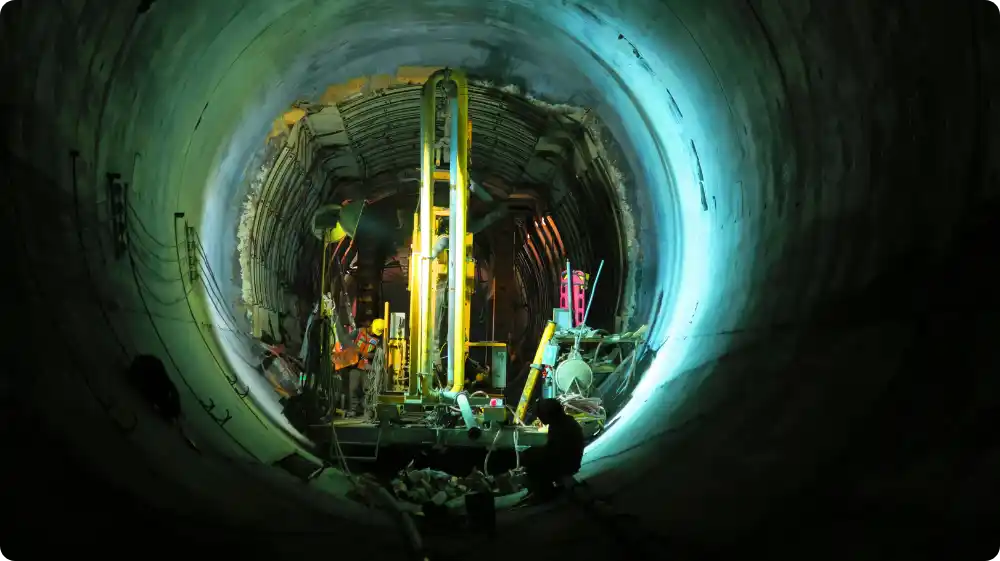

When people hear the term “confined space,” they often envision tight, cramped crawl spaces or small chambers. In reality, the definition is much broader. A confined space is any area that is substantially enclosed, where serious injury could occur from hazardous substances, poor ventilation, or restricted entry and exit. Importantly, even large structures such as tunnels, silos, or storage tanks may be classed as confined spaces if they expose workers to these dangers.

Under the Confined Spaces Regulations 1997, a confined space is identified not just by its size but by the risks it presents. This means that a place which appears routine can still be hazardous if it contains toxic gases, lacks oxygen, or limits the ability to escape during an emergency. Examples range from the obvious to the unexpected; sewers, drainage systems, boilers, pipelines, and silos all qualify, each bringing unique hazards that demand careful planning and strict safety controls.

Why is Working in Confined Spaces So Dangerous?

Confined spaces are some of the most hazardous environments in the workplace. Even routine tasks can turn deadly if risks are not identified and controlled. Their danger lies in the mix of restricted movement, poor ventilation, and hidden hazards that can escalate within moments.

Main Hazards and Risks

- Toxic or flammable gases: Exposure to harmful vapours or risk of explosions.

- Low oxygen levels: Can quickly lead to unconsciousness or suffocation.

- Engulfment: Loose materials, such as grain, sand, or liquids, can trap workers.

- Restricted entry and exit: Escapes and rescues are difficult in emergencies.

- Physical risks: Include Heat stress, poor lighting, and cramped working conditions.

These hazards often strike without warning, which is why confined space incidents are so severe and frequently result in fatal outcomes. Real-life cases, such as workers overcome by fumes in tanks or suffocated in silos, highlight the speed at which conditions can become deadly and why regulations are so strict.

Key Safety Measures for High-Risk Work

Because confined spaces pose life-threatening hazards, safety measures are crucial before any work commences. The goal is not only to protect workers but also to ensure compliance with UK law. A thorough approach combines risk assessments, protective equipment, training, and emergency planning.

Risk Assessments and Safe Systems of Work

Before entry, a detailed risk assessment must be conducted to identify potential hazards and determine whether the task can be avoided altogether. If work must proceed, a safe system of work should be established, including permits-to-work, monitoring, and clear procedures for every stage of the task.

Personal Protective Equipment (PPE) and Ventilation

Where risks cannot be eliminated, PPE becomes vital. Depending on the environment, this may include breathing apparatus, gas detectors, harnesses, and protective clothing. Ventilation systems should also be used to provide fresh air, dilute toxic fumes, or prevent heat stress.

Training, Supervision, and Emergency Planning

Workers entering confined spaces must be trained to recognise hazards, use equipment correctly, and respond in emergencies. Adequate supervision ensures procedures are followed, while a well-rehearsed emergency plan guarantees that rescue operations can begin immediately if something goes wrong.

Taken together, these measures significantly reduce the risks associated with confined space work and form the basis for legal compliance under the Confined Spaces Regulations 1997.

The Confined Spaces Regulations 1997 Explained

The Confined Spaces Regulations 1997 were introduced to reduce accidents and fatalities in high-risk environments. They place clear duties on both employers and workers, ensuring that confined space tasks are only undertaken when vital and always under strict safety controls.

Key Employer Duties Under the 1997 Regulations

The regulations define what constitutes a confined space and outline specific employer responsibilities. If work cannot be avoided, employers must:

- Conduct a thorough risk assessment.

- Establish and maintain a safe system of work.

- Provide training, supervision, and protective equipment.

- Implement effective emergency and rescue procedures.

These duties form the legal backbone of safe confined space work.

Updates and Guidance from 2021

While the 1997 regulations remain the foundation, updated guidance issued in 2021 strengthened best practices. It highlighted the use of modern safety technology, such as portable gas monitors, and reinforced the need for competent supervision and robust emergency planning.

Responsibilities of Employers and Employees

- Employers must plan, supervise, and control confined space work while ensuring that proper emergency arrangements are in place.

- Employees must follow training, use equipment correctly, and promptly report any hazards.

By combining the requirements of the 1997 regulations with the 2021 guidance, organisations can maintain compliance and significantly reduce the risks of confined space work.

How to Identify Work That Falls Under the Regulations

Recognising whether an area qualifies as a confined space is not always straightforward. A space doesn’t have to be small or fully sealed to be considered one; the real issue is whether foreseeable risks could cause serious harm to anyone inside.

Criteria | Examples |

Enclosed or largely enclosed | Storage tanks, tunnels, silos |

Restricted entry or exit | Manholes, trenches, pipelines |

Dangerous conditions present or likely to develop | Toxic gases in drainage systems, oxygen deficiency in silos, risk of flooding in ducts |

The Confined Spaces Regulations 1997 also highlight two fundamental requirements before work begins:

- Avoid entry unless absolutely necessary.

- If entry cannot be avoided, follow a safe system of work that includes risk assessments, protective measures, and emergency arrangements.

By applying these principles, employers and workers can make informed decisions about whether a space legally qualifies as confined and what safety measures must be enforced.

Best Practices for Staying Safe On-Site

Confined space work always carries risks, but following best practices can significantly reduce these risks. The most effective approach begins with avoiding confined space entry whenever possible. Alternatives such as remote tools or external access should be explored first.

When confined space work cannot be avoided, it must be carried out under strict controls. Permits-to-work play a central role, setting out the steps for safe entry, monitoring conditions, and assigning responsibilities.

Beyond formal systems, cultivating a culture of readiness is crucial. Emergency plans must be more than a document; they should be well-practised and supported by staff who know precisely how to respond. In workplaces where safety culture is prioritised, confined space accidents are far less likely to occur.

Conclusion: Ensuring Safe and Compliant Work

Confined space incidents often occur when risks are underestimated or procedures are ignored. That is why the Confined Spaces Regulations 1997 place such emphasis on prevention, safe systems of work, and emergency arrangements. Guidance published in 2021 further highlights the importance of modern monitoring tools and competent supervision.

However, proper safety goes beyond legal compliance. The most effective organisations create a culture where every worker understands the risks, every supervisor enforces procedures, and every emergency plan is ready to be implemented. When safety becomes an integral part of workplace culture, confined space accidents are not only reduced; they are prevented.

Boost Your Workplace Safety with Hurak’s Health & Safety Courses

Hurak offers a range of accredited Health & Safety qualifications to help you comply with regulations, prevent risks, and create safer workplaces.

Health and Safety in the Workplace

- Level 2 Health and Safety in the Workplace

- Level 3 Health and Safety in the Workplace

- IOSH Working Safely Course

- IOSH Managing Safely Course and Certificate

- IOSH Working Safely Course

Fire Safety Training

- Fire Marshal (Fire Warden) Course

- Fire Safety Manager Advanced Diploma

- NEBOSH Certificate in Fire Safety

Want more options? Browse All Health & Safety Courses at Hurak.