Crane operations are a common sight on construction sites, manufacturing yards, and industrial projects across the UK. While they make it possible to move heavy materials with ease, cranes also present serious risks. Accidents involving cranes can cause severe injuries, property damage, and in some cases, even loss of life. That’s why understanding crane lifting hazards and how to control them is crucial for anyone working around lifting equipment, from site operatives to supervisors and managers.

This article examines the most common crane lifting hazards, the control measures that mitigate them, and the crucial role of training in creating a safer workplace. It’s written in plain English and is intended for anyone looking to improve their knowledge, whether you’re a beginner or a seasoned professional.

Why Is Crane Lifting Safety So Important?

Crane-related incidents often result from predictable causes, including a poorly secured load, unclear communication, or failure to identify a hazard before a lift. According to the UK’s Health and Safety Executive (HSE), lifting operations continue to account for serious injuries and fatalities each year.

Crane lifting doesn’t just involve the operator; it’s a coordinated task between supervisors, slingers, signalers, and ground workers. When a single part of that team breaks down or fails to follow procedure, the risks escalate quickly. From crushing injuries to electrocution or crane collapse, the potential consequences of poor planning or oversight are too significant to ignore.

🛠️ New to Site Work? Start Here

The Health and Safety Awareness (HSA) course covers the basics every site worker should know, including lifting zones, PPE, and hazard spotting.

Explore the Health and Safety Awareness course.

Common Hazards in Crane Lifting Operations

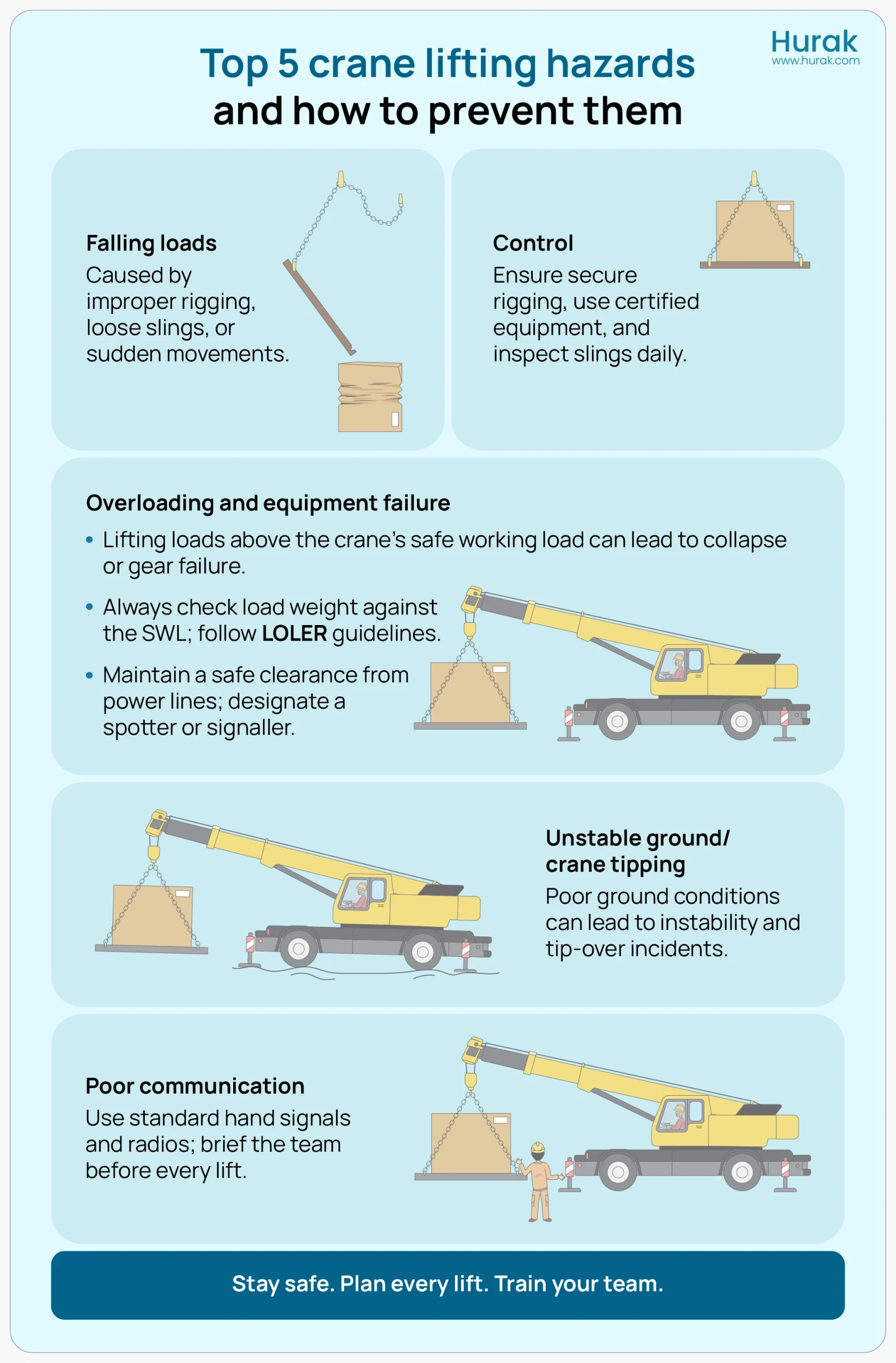

Falling Loads

One of the most dangerous hazards during crane operations is a load becoming detached mid-lift. This can happen due to improper rigging, overloading, or worn lifting equipment. The weight and momentum of a falling load can be fatal to anyone beneath or nearby. Ensuring secure attachment and regular inspection of lifting gear is vital.

Overloading and Equipment Failure

Every crane is designed with a maximum Safe Working Load (SWL). When this limit is exceeded, structural failure is likely to occur. Even if the crane appears to handle the weight, stress damage can accumulate, compromising future safety. Equipment failures also occur when slings, hooks, or shackles are damaged or have exceeded their usable lifespan.

Unstable Ground and Crane Tipping

Cranes rely on a stable base. Soft ground, uneven surfaces, or working too close to open trenches can cause a crane to become unbalanced and tip. Weather conditions, such as rain or high winds, can exacerbate this instability. A site that’s poorly assessed or prepared becomes a serious risk for crane operations.

Electrocution from Overhead Power Lines

Cranes often operate near overhead electrical lines, particularly on urban or infrastructure sites. If a crane comes into contact with live wires, the risk of electrocution is high, not only to the operator but also to anyone in contact with the crane or the ground in the area. Planning safe distances and monitoring boom heights are essential precautions.

Poor Communication Among Team Members

Effective crane lifts require a well-informed and briefed team. If communication breaks down between the crane operator, signaler, or slinger, mistakes can occur, such as lifting before the load is secured or swinging the load into an unsafe area. Hand signals, radios, and a clear chain of command help prevent these issues.

Control Measures That Reduce Risk

Thorough Planning and Risk Assessment

Before any lifting operation begins, a risk assessment should be carried out by a competent person. This includes identifying the type of lift, load weight, ground conditions, weather forecasts, and potential obstacles. Every lift should be treated as a unique task, even when it is routine because conditions can vary from day to day.

In the UK, this planning falls under the Lifting Operations and Lifting Equipment Regulations (LOLER). Supervisors responsible for implementing these plans must also ensure all team members are aware of their roles. If you’re stepping into such a role, the SSSTS course offers targeted training on how to supervise lifting activities safely and legally.

Equipment Checks and Regular Inspections

Lifting equipment should be checked visually before each use and formally inspected on a scheduled basis. Defective gear, whether it’s a frayed sling or a misaligned hook, must be removed from service immediately. A competent person with knowledge of LOLER requirements should carry out formal inspections.

Neglecting inspections doesn’t just increase the risk of accidents; it may also result in legal penalties and fines. A deeper understanding of risk and hazard control can help workers spot potential dangers before they escalate.

Thorough Planning and Risk Assessment

Before any lifting operation begins, a risk assessment should be carried out by a competent person. This includes identifying the type of lift, load weight, ground conditions, weather forecasts, and potential obstacles. Every lift should be treated as a unique task, even when it is routine because conditions can vary from day to day.

💪 Protect Your Back and Team

From rigging to load preparation, poor technique can lead to injury. The Manual Handling Training course teaches safer and smarter lifting on-site.

Explore Manual Handling Training

Creating a Controlled Lifting Zone

During crane operations, the lift area should be clearly marked and access restricted. Barriers, cones, or signage can be used to prevent unauthorised entry. The lifting zone should never be crossed while a load is suspended. Extra care should be taken when visibility is poor or ground conditions are unpredictable.

Managers also have a duty to stop lifting operations if conditions become unsafe, for example, due to strong winds or poor visibility. This responsibility underscores the importance of effective leadership on-site and a thorough understanding of health and safety legal frameworks.

Training and Competence

Proper training underpins every successful lifting operation. Everyone involved, from crane operators to ground workers, must be adequately trained and competent in their respective roles. Supervisors must not only understand the lifting process but also how to identify if team members are fit for duty.

For those in a leadership position, courses like IOSH Managing Safely are valuable for understanding broader health and safety principles across the site.

Clear, Unambiguous Communication

Whether via hand signals, radios, or verbal instructions, communication during a lift must be consistent and understood by all parties. Misunderstood instructions can cause the crane to move at the wrong time or position the load in a dangerous manner. Everyone should be briefed beforehand, and only designated personnel should give instructions to the crane operator.

Legal Duties and Your Role

UK law requires that lifting operations by:

- Planned adequately by a competent person

- Supervised and carried out safely

- Conducted using suitable and well-maintained equipment

These legal duties fall under the Health and Safety at Work Act 1974, LOLER (Lifting Operations and Lifting Equipment Regulations), and PUWER (Provision and Use of Work Equipment Regulations). Non-compliance can result in prosecution, substantial fines, and reputational damage for companies, as well as severe injuries for workers.

Understanding your legal responsibilities is part of being a responsible professional. The more informed you are, the better equipped you’ll be to protect both your team and yourself.

🏗️ Lead Safer Sites

Managing crane lifts or high-risk tasks? The CITB SMSTS course equips you with the tools to plan, lead, and remain compliant on-site.

Explore the SMSTS course

The Value of Professional Training

Training is more than a compliance requirement; it builds competence and confidence on-site. Whether you’re learning how to rig loads correctly, supervise a lifting team, or enforce safe working practices, training sharpens your ability to recognise and control risks.

It also supports career development. Supervisors and site managers with accredited safety training are not only safer but also more employable. Those new to construction can start with a foundation course, such as Health and Safety Awareness, while experienced professionals can expand their knowledge through advanced options.

FAQs

What are the most common hazards during crane lifting operations?

Some of the most common crane lifting hazards include falling loads, overloading, unstable ground, contact with overhead power lines, and poor communication among the lifting team. Each of these can result in serious injuries or fatalities if not appropriately managed. Understanding these lifting hazards and control measures is essential for safe crane operation, especially on busy construction sites.

Who is responsible for crane lifting safety on site?

The responsibility for crane lifting safety is shared between several roles, including the crane operator, slinger/signaller, lifting supervisor, and site manager. However, under UK law, employers must ensure that lifting operations are properly planned and supervised by competent individuals. Supervisors trained in lifting operation safety are better equipped to identify and control risks before a lift takes place.

What legal regulations apply to crane operations in the UK?

Crane operations fall under multiple UK regulations, most notably:

- LOLER (Lifting Operations and Lifting Equipment Regulations 1998)

- PUWER (Provision and Use of Work Equipment Regulations 1998)

- Health and Safety at Work Act 1974

These regulations require employers to plan lifts properly, use suitable equipment, and ensure all operators are competent. Non-compliance with these laws can result in prosecution or serious harm.

How can I make sure a crane lift is safe before it begins?

Safe crane lifting begins with a clear lift plan, prepared by a qualified person. This plan should cover the load weight, crane type, lifting method, ground conditions, and environmental factors such as wind speed. Daily visual checks of the crane and lifting gear should be conducted, and all personnel involved should receive a briefing before the lift. These steps form part of standard lifting operation safety procedures.

Do I need formal training to be involved in crane lifting operations?

Yes. While roles vary, anyone involved in crane operations, whether as an operator, signaler, or supervisor, should undergo appropriate safety training. Courses like CITB SSSTS or SMSTS are specifically designed to teach site personnel how to manage risks associated with crane operations and comply with relevant legislation. Even general safety awareness or manual handling courses are helpful for operatives working near lifting zones.

What should I do if the lifting equipment looks worn or damaged?

If any lifting equipment, such as slings, hooks, or shackles, appears worn or defective, it should be removed from use immediately and reported to a supervisor. Using damaged equipment significantly increases the risk of failure during a lift. Regular inspections and maintenance are key elements of crane lifting safety, and they are required by law under LOLER.

How often should cranes and lifting accessories be inspected?

In general, lifting accessories (such as slings or chains) should be formally inspected every 6 months, and cranes or lifting appliances should be inspected every 12 months or more frequently if specified by a risk assessment. Pre-use checks should be conducted daily before commencing crane operations. These inspections must be performed by a competent person and documented.

What role does communication play in safe crane lifting?

Communication is vital in any lifting operation safety strategy. Operators must receive precise instructions from a designated signaler using agreed-upon hand signals or radios. Miscommunication is one of the leading causes of lifting accidents, especially on busy construction sites. Toolbox talks and lift team briefings are simple but effective ways to reduce this risk.

Can weather conditions affect lifting operations?

Yes, weather plays a critical role in crane safety. High winds, rain, and poor visibility can all affect load stability and crane control. Lifts should be postponed or cancelled if conditions are unsafe. This is why every lift plan should include environmental monitoring as part of its risk controls.

What’s the best course to take if I want to supervise lifting operations?

If you’re looking to move into a supervisory role and oversee crane activities on-site, the CITB SSSTS (Site Supervisor Safety Training Scheme) is highly recommended. It covers how to plan safe lifting operations, understand site hazards, and ensure compliance with legal duties. For those managing more complex or high-risk projects, the SMSTS (Site Management Safety Training Scheme) provides a broader foundation in health and safety management.