Kitchen hazards are potential sources of danger within a kitchen environment that can cause injury, illness, or damage. These include physical risks such as slips, cuts, and burns, as well as biological and chemical hazards that affect food safety.

Understanding and managing kitchen hazards is essential for anyone working in or managing a commercial kitchen. Being aware of risks helps prevent accidents, protects staff wellbeing, and ensures smooth daily operations.

In this article, we will guide you through the most common kitchen hazards and ways to identify and prevent them.

Why Is It Important To Understand Kitchen Hazards?

Understanding kitchen hazards is crucial to creating a safer and more efficient working environment. Unaddressed hazards not only pose a risk to staff but can also lead to serious incidents, such as food contamination, fires, or equipment damage, all of which can disrupt service and impact the business.

By identifying risks early, you can take simple preventative steps to avoid accidents, maintain food safety standards, and ensure smooth day-to-day operations. To effectively manage these risks, let’s explore the various types of hazards commonly found in kitchen settings.

Types Of Kitchen Hazards

Kitchens are busy environments where hazards come from many sources. Here are the most common types:

Physical Hazards

Injuries caused by physical objects or environmental conditions.

- Slips and trips from wet floors or food spills.

- Cuts from knives or broken glass.

- Burns from hot surfaces or boiling liquids.

- Falling objects like pans or stacked containers.

Maintaining cleaning habits and consistent clean as you go routines helps minimise these physical hazards through better organisation and cleanliness.

Chemical Hazards

Exposure to harmful substances.

- Cleaning agents not rinsed off properly.

- Food additives misused.

- Chemical storage near food items.

Biological Hazards

Caused by harmful microorganisms.

- Bacteria like Salmonella or E. coli in undercooked food.

- Mould growing in damp areas.

- Viruses spread through unclean surfaces.

Understanding how these microorganisms contribute to the 4 types of food contamination can help food handlers prevent biological hazards more effectively.

Ergonomic Hazards

Strain or injury due to poor posture or repetitive movement.

- Lifting heavy items improperly.

- Standing for long periods without support.

- Repetitive chopping causing muscle strain.

Electrical Hazards

Risks involving faulty or unsafe electrical equipment.

- Exposed wires or damaged plugs.

- Water near electrical appliances.

- Overloaded sockets.

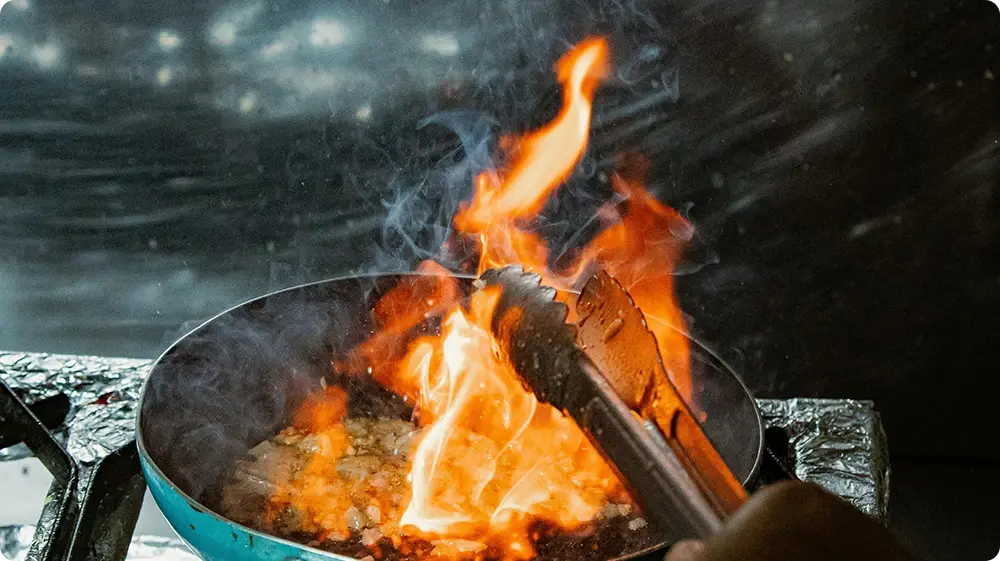

Fire Hazards

Common in kitchens due to high heat and flammable materials.

- Grease buildup near open flames.

- Unattended cooking.

- Blocked fire exits.

Equipment Hazards

Injuries from improper use or maintenance of kitchen tools.

- Malfunctioning machines like slicers or fryers.

- Improper training on equipment use.

Cross-Contamination

Transfer of harmful substances between surfaces, food, or equipment.

- Raw meat juices touching ready-to-eat foods.

- Unclean chopping boards or utensils used for multiple foods.

Using separate tools based on the chopping board colours system, and consistently applying best practices to prevent cross contamination, can significantly reduce these risk

Temperature Hazards

Danger from improper temperature control.

- Food left in the temperature danger zone.

- Inadequate cooling or reheating.

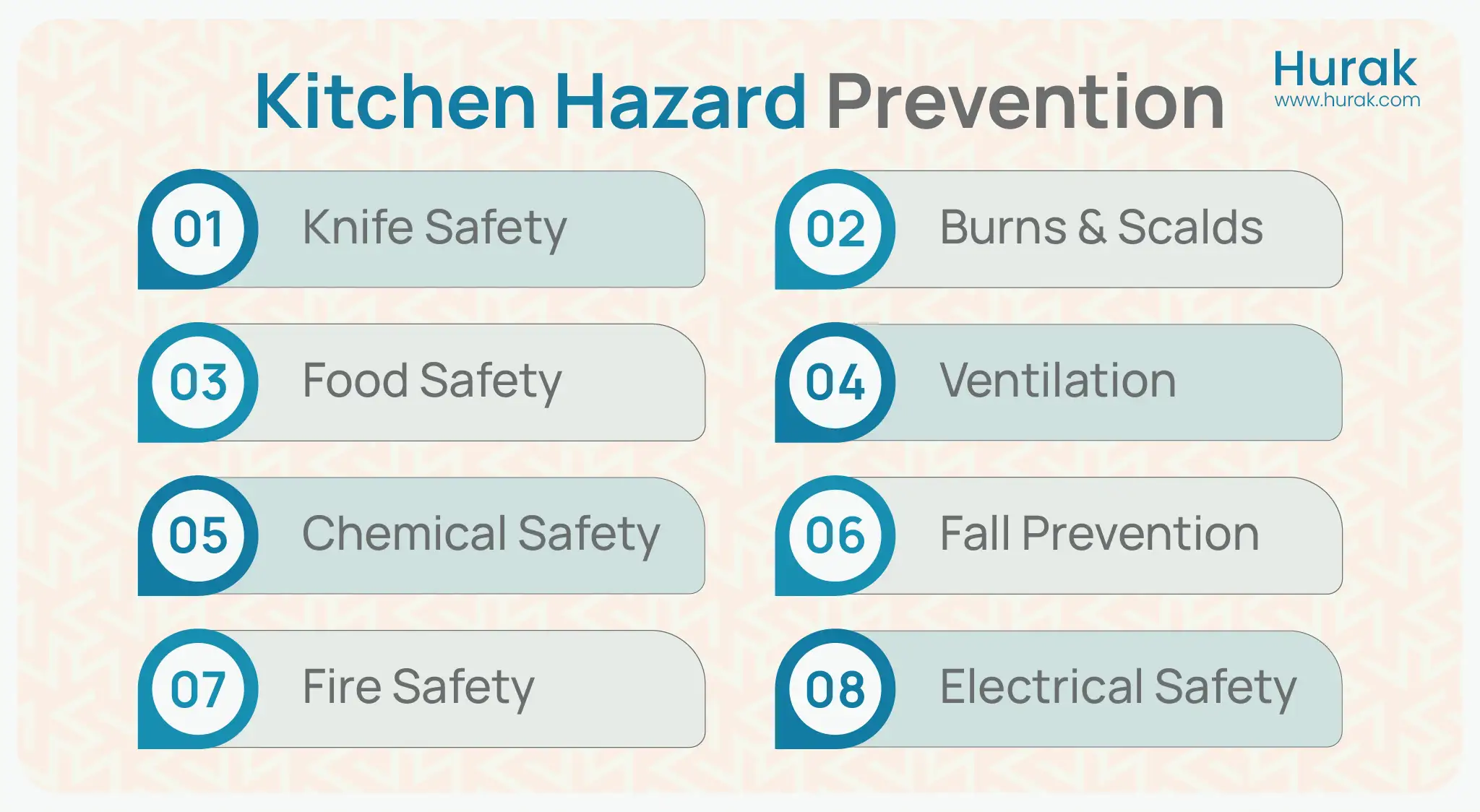

How To Prevent Kitchen Hazards

Understanding kitchen hazards is the first step; implementing preventive measures is equally important to ensure a safe kitchen environment. Prevention starts with good habits, clear protocols, and regular maintenance.

Here are some essential tips for a safer kitchen:

Knife Safety

- Keep knives sharp and well-maintained; dull blades can slip more easily and cause accidents. (Be extra careful while using sharp knives.)

- Always use a non-slip cutting board.

- Store knives securely in a knife block or magnetic strip, not loose in drawers.

Example: During a busy shift at a catering event, a sous-chef used a damp cutting board and a dull knife to slice tomatoes. The knife slipped and caused a deep cut to the hand.

Tip: Always use a dry, non-slip cutting board and keep knives sharp to reduce the risk of slipping and injury.Burns And Scalds

- Use oven mittens or pot holders when handling hot pans or trays.

- Turn pot and pan handles inward to prevent accidental knocks.

- Tie back long hair, and avoid wearing loose clothing near hot surfaces.

Example: A kitchen worker grabbed a hot tray with bare hands during a busy lunch service and suffered serious burns. The oven mitts were stored too far from the oven.

Tip: Keep mitts and pot holders close to ovens and hotplates to encourage use, even when rushed.Food Safety

- Cover cuts with waterproof dressings and wear gloves if needed.

- Store raw meat, poultry, and seafood on the lowest shelf in the fridge to prevent drips and cross-contamination.

- Keep the fridge at or below 4°C and the freezer at -18°C.

- Label and date leftovers, and discard any that are out of date.

- Avoid leaving cooked food out at room temperature for more than 2 hours./li>

Example: At a cafe, raw chicken was stored above salad ingredients in the fridge. Juices leaked overnight, contaminating ready-to-eat food and causing food poisoning.

Tip: Always place raw meats on the bottom shelf and regularly inspect overall fridge organisation. Following proper guidelines on how to organise your fridge helps minimise contamination and maintain food safety standards.

Chemical Safety

- Store cleaning products away from food and prep areas, ideally in a clearly labelled cabinet.

- Always rinse food contact surfaces after using chemical cleaners.

- Follow the manufacturer’s instructions when using cleaning agents.

Example: A cleaner at a takeaway used bleach instead of a food-safe sanitiser because bottles weren’t clearly labelled. The kitchen had to be fully sanitised, resulting in a full day’s closure.

Tip: Use clearly labelled containers and ensure all staff are trained on safe chemical use. Adopting consistent protocols based on the 6 Stages of cleaning and promoting a clean as you go culture ensures safe and compliant workspaces.

Preventing Slip, Trip And Fall

- Wipe up spills immediately.

- Use non-slip mats in wet areas.

- Keep walkways clear of obstacles and clutter.

Example: A waiter slipped on water near the sink while carrying hot soup. The spill hadn’t been cleaned or signposted, leading to injury and a compensation claim.

Tip: Clean up spills instantly and place wet floor signs when needed.Fire Safety

- Keep a fire extinguisher nearby and ensure staff know how to use it.

- Clean grease from ventilation hoods and filters on a regular basis.

- Never leave cooking unattended.

- Keep flammable materials (like cloth towels or packaging) away from heat sources.

Example: A cloth towel left near a gas stove caught fire. The team panicked and didn’t know how to use the extinguisher. The fire caused significant kitchen damage.

Tip: Train staff in basic fire response and keep flammable items away from heat.

🔥 Want to Be Better Prepared?

👉 Take the Fire Marshal / Fire Warden Online Course – ideal for anyone responsible for fire safety in the workplace.

Electrical Safety

- Unplug small appliances, such as blenders or toasters, when not in use.

- Don’t use appliances with damaged cords or plugs.

- Avoid overloading power sockets — use surge-protected strips if needed.

- Keep electrical devices away from water.

Example: An employee was electrocuted while turning on a toaster located near a leaking dishwasher. The plug socket was not waterproof.

Tip: Keep electrical appliances dry and conduct regular safety inspectionsAir Quality And Ventilation

- Use extractor fans or open windows to reduce smoke and steam while cooking.

- Clean ventilation systems and filters regularly to prevent grease build-up and fire risks.

Example: In a takeaway, grease-clogged vents led to thick smoke and breathing issues. Staff had to evacuate and call the fire brigade.

Tip: Schedule regular vent cleaning to prevent build-up and maintain air quality.General Safety And Hygiene

- Educate all kitchen staff on basic safety procedures — including knife handling, first aid, and fire response.

- Keep a first aid kit in a readily accessible location, and ensure that someone on-site is trained in first aid.

- Dispose of rubbish frequently and clean bins to prevent pests.

Example: A team member cut their hand, but no one knew where the first aid kit was, which delayed treatment.

Tip: Ensure all staff know where safety equipment is stored and who’s trained in first aid.

Recovering From Kitchen Hazards And Maintaining Safety

Even with thorough risk assessments and control measures in place, kitchen hazards can still occur. When they do, it is essential to respond quickly and effectively to minimise damage.

Prioritise Safety First

The immediate priority must be to ensure the safety of all kitchen staff. If necessary, call emergency services for any urgent dangers. Make sure any ongoing hazards are controlled before proceeding. For hazards involving gas, it is advisable to hire a gas detector to confirm that no dangerous leaks remain before resuming kitchen operations.

Assess And Address the Damage

Once everyone is safe, carefully assess the extent of the damage caused by the hazard. This evaluation will guide your next steps, whether they involve cleaning up spills, repairing equipment, or addressing contamination.

Clean And Sanitise Thoroughly

To prevent the spread of bacteria or other harmful substances, clean and sanitise any affected areas promptly and thoroughly. Following proper cleaning protocols helps restore a safe working environment.

Document The Incident

Keep detailed records of the hazard incident, including what happened, when it occurred, who was involved, and the actions taken. This documentation is valuable for reviewing procedures and preventing future risks.a

Review And Update Procedures

Use the incident as a learning opportunity. Review your current safety procedures and make necessary adjustments to reduce the chances of a similar hazard occurring again.

Notify Relevant Authorities If Needed

Depending on the severity of the incident, inform the relevant authorities, such as local health departments, regulatory bodies, or insurance providers, to ensure compliance and receive necessary support.

Support Your Team

Hazard incidents can be stressful for staff. Offer support where needed, including counselling or practical assistance, to help employees recover and maintain morale.

Resume Normal Operations

After the hazard has been addressed and the kitchen is safe, resume normal operations as quickly as possible to minimise disruption and financial impact.

Conclusion

Effectively managing kitchen hazards is essential to maintaining a safe, efficient, and compliant workplace. By conducting regular risk assessments, responding promptly to issues, and continuously improving safety practices, you protect your team and minimise costly disruptions. Staying informed and prepared ensures your kitchen runs smoothly every day.

Make Kitchen Safety Your Priority

Sign up for our certified Food Safety courses now!

FAQs

What are the most common kitchen hazards?

The most common kitchen hazards include slips, trips, cuts, burns, fire risks, and food contamination hazards. These can occur due to poor housekeeping, improper storage, inadequate safety training, or improper food handling practices.

What makes food hazardous?

Food becomes hazardous when it is exposed to harmful substances, such as bacteria, chemicals, or foreign objects. Poor hygiene, cross-contamination, incorrect cooking temperatures, and expired ingredients are examples of what make food hazardous.

What are the physical hazards in food?

Physical hazards in food refer to foreign objects, such as glass, plastic, hair, or metal fragments, that can accidentally contaminate food. These can cause injury and are a serious breach of food safety standards.

How can I prevent contamination hazards in the kitchen?

To reduce contamination hazards of food, you should:

- Store raw and cooked foods separately

- Use colour-coded chopping boards

- Clean as you go

- Practice good hand hygiene

- Follow the 6 stages of cleaning

Why is temperature control important in the kitchen?

Temperature control helps prevent the growth of harmful bacteria. Food should be stored outside the temperature danger zone (5°C – 63°C) to remain safe. Always cook, chill, and store foods at the right temperatures.

What safety equipment is essential in a kitchen?

Essential kitchen safety equipment includes:

- Fire blankets and extinguishers

- First aid kits

- PPE (like gloves and aprons)

- Non-slip mats

- Clearly labelled chemical storage units

How can I reduce the risk of fire in the kitchen?

To prevent fire hazards:

- Keep flammable materials away from heat sources

- Regularly clean grease traps and extractor fans

- Never leave cooking unattended

- Train staff on using fire safety equipment

For more, see our article on the difference between flammable and combustible materials.

What training should staff have to manage kitchen hazards?

Staff should complete food safety and hygiene training and be familiar with HACCP principles, proper cleaning methods, and safe food handling practices. Regular refresher training ensures safety practices stay up to date.

How often should kitchen equipment be checked?

Kitchen equipment should be inspected regularly, ideally on a daily or weekly basis, depending on its usage. Scheduled maintenance helps prevent accidents caused by faulty or worn-out tools.