Manual handling is one of the main factors contributing to occupational accidents and illness in the UK. It was the second-leading cause of work-related ill health, accounting for 30% of instances, and caused 8.9 million lost working days. There were 480,000 total cases, including long-standing ones, of work-related musculoskeletal illnesses in 2019–20, including 152,000 new cases (one of the most frequent repercussions of improper manual handling techniques).

Understanding what influences a person’s capacity for safe task performance is essential. These figures show that the effects of inadequate manual handling are too widespread and can seriously impact people’s health. Therefore, you must comprehend proper manual handling, weight restrictions, and handling practices to guard against bodily harm.

Businesses in the UK are required by law to safeguard the health and safety of their employees. Therefore, employing safe manual handling practices and abiding by weight restrictions will guarantee that your company complies with the requirements of the pertinent UK legislation and guidance guidelines.

Your training in the principles and techniques of safe manual handling will be sufficient thanks to our manual handling training. A variety of our health and safety courses are also available here.

This article will comprehensively review the manual handling weight restrictions and recommendations provided by the Health and Safety Executive and outlined in the law (HSE).

Manual Handling Weight Limits for Lifting

There are no set restrictions on how much manual handling and lifting can be done at work because it relies on many variables, including the nature of the task and the worker’s unique skills.

Employers are required to take adequate action to minimise the risk of injury caused to employees by manual handling activities to the lowest level reasonably possible under the Manual Handling Operations Regulations (MHOR) 1992. Different weight restrictions and techniques will be needed to achieve this depending on the sort of manual handling activity.

The hierarchy of measures outlined by the MHOR states that production lines and other forms of automation should always be used before manual handling procedures are avoided. If this is not feasible, the responsibility holder must evaluate the hazards presented by manual handling activities at work and decide how to control them. Perform a risk analysis of the manual handling operations as part of this. Then, to lessen the dangers to people’s health and safety, they must implement the required safety measures.

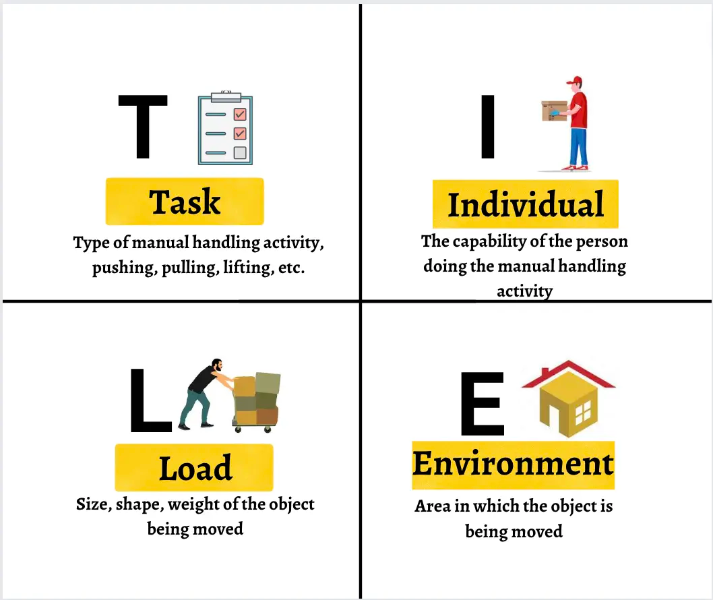

During the risk assessment for manual handling, duty holders must take into account the following 4 important factors:

- Task – For instance, how much time it will take, how often it will be performed, whether it is repetitive, whether it offers enough time for rest or recovery, and whether it requires twisting, stooping, or reaching upwards. All of these factors may influence how demanding the work is.

- Individual – Everyone has different physical abilities and limitations depending on various factors, such as age or physical make-up. New or pregnant mothers, persons with impairments, and people returning to work after an injury may all be particularly at risk. Since no two persons are similar, employers must tailor the work and safety procedures to each employee’s talents to ensure that everyone is equally protected from health and safety concerns.

- Load – It can be challenging for a person to secure a firm grip and maintain control of the weight if it is too large or bulky, challenging to hold, and has a fluctuating centre of gravity (for example, if it contains liquid). The body might be put under extra stress as a result of this.

- Environment – The task will be more challenging and consequently more physically demanding to do, for instance, if there isn’t enough room in the area for the person managing the weight to move comfortably, if the floor is uneven or has different levels, or if the person can’t see clearly. High workloads, short deadlines, and a lack of control over the task and working methods can all cause psychological reactions that increase the risk for people.

TILE, or occasionally LITE, is the name of these four elements. They are crucial when determining safe lifting techniques and weight restrictions for particular manual handling activities. The MHOR and related HSE manual handling advice publications recommend weight restrictions for lifting, carrying, pushing, pulling, and team actions in light of these variables and other guidance.

This information must be considered in the context of the particular manual handling activities at your place of employment because there is no one size fits all solution. However, the guidelines are helpful resources for the individual in charge of establishing the essential manual handling restrictions.

Safe Lifting Weights

Although the MHOR does not specify weight restrictions, the HSE provides some lifting and lowering best practices. Although the HSE claims they employ “broad assumptions or generalisations where, if met, the risk of injury is deemed to be low,” they should not be referred to as “safe limits” because this depends on all the elements involved, as was noted above. Work performed outside these advised ranges is probably more likely to result in an injury.

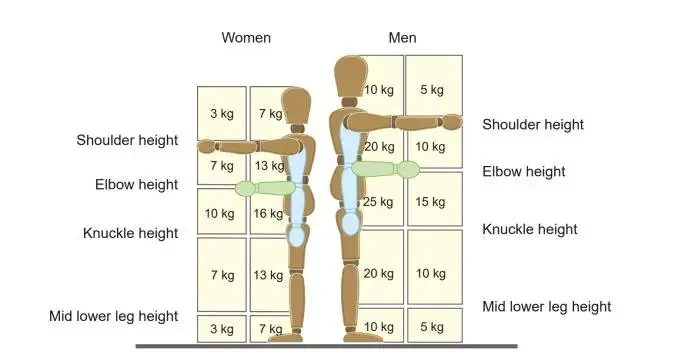

Based on information from the general population, the HSE’s lifting and lowering risk filter specifies overall safe lifting capacities for men and women as follows:

This demonstrates that the average man’s safe upper limit for manually handling a load is 25 kg, and the average woman’s is 16 kg.

It’s important to remember that this only applies if the person carrying the load can hold it close to their body and at knuckle height. It is no longer safe to manage a 25 kg burden if the load moves across the zones, such as when you lift a box from knuckle height to a shelf at shoulder height. The lower weight must be used if the load is anticipated to move across zones while the task is being completed.

The fact that these risk filters only apply to manual handling operations where the load:

- Simple to hold in both hands.

- Is working under appropriate conditions.

- Can be supported using secure lifting and handling techniques with the worker’s body in a stable position.

- Enables holding against the body.

- It is not carried more than 10 metres without stopping.

- Does not impede the person’s ability to walk normally.

- Does not interfere with the carrier’s vision.

- Requires neither much below knuckle height nor much over elbow height for the carrier’s hands.

- without having to be hoisted first, it can be safely put upon the shoulder The filter values can be used up to 20 metres in this circumstance.

Certain elements will necessitate a complete evaluation of manual handling activities and possibly differing weight limitations and handling techniques.

For instance, if the weights are greater than those in the risk mentioned above, filter if the handling requires twisting, if there is more than one lift every two minutes, if a team is involved, if the weights vary significantly, if the load is challenging to grasp, and if the person is at an elevated risk (e.g. those with disabilities or a recent injury).

Safe Lifting Weights and Techniques

Duty holders can assess the most frequent risk elements in lifting and lowering, carrying, and team handling tasks using the HSE Manual Handling Assessment Charts (the MAC tool). It uses a number of visuals and infographics to help illustrate how different elements enhance the amount of risk and how each risk range will demand careful thought on how to preserve people’s health.

For instance, determining the weight and frequency of the loads involved in lifting is the first topic covered in this tutorial. It demonstrates how the level of risk rises as lift rate and weight increase.

As opposed to lower bands, the risk has increased as tasks move into a new colour band, and more safety controls are likely to be needed.

The MAC tool addresses the following manual handling risk areas:

Lifting Operations:

- Load weight/frequency.

- Vertical lift zones.

- Postural constraints.

- Hand distance from the lower back.

- Floor surface.

- Torso twisting and sideways bending.

- Grip on the load.

- Environmental factors.

Carrying Operations:

- Load weight/frequency.

- Asymmetrical torso or load.

- Floor surface.

- Hand distance from the lower back.

- Obstacles on the route.

- Carry distance.

- Postural constraints.

- Grip on the load.

- Environmental factors.

- Load weight.

- Vertical lift zones.

- Hand distance from the lower back.

- Grip on the load.

- Torso twisting and sideways bending.

- Carry distance.

- Postural constraints.

- Communication, coordination, and control.

- Floor surface.

- Obstacles on the route.

- Environmental factors.